Wheat powder air drive vacuum conveyor vacuum powder transport system

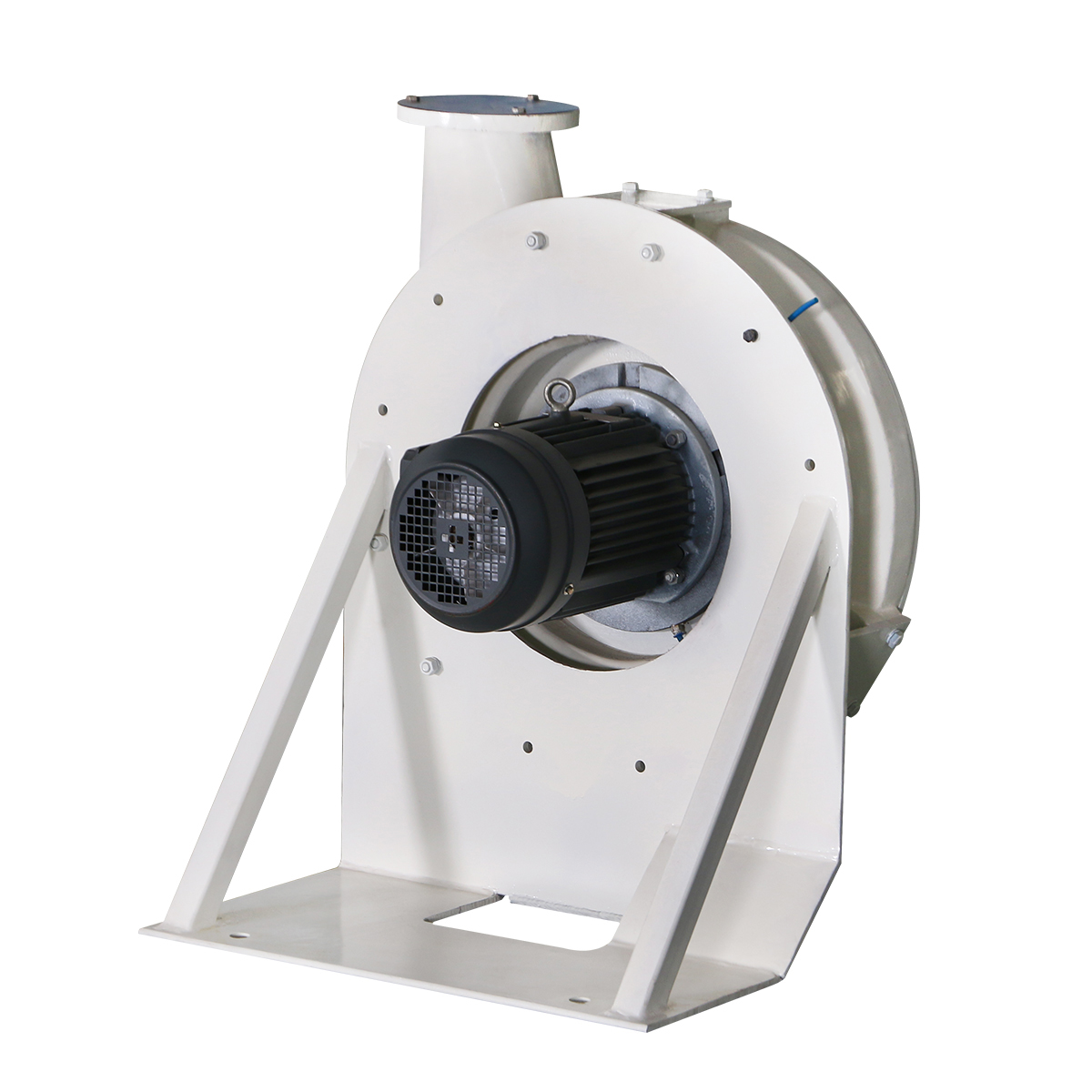

Pneumatic conveying is a method of conveying materials through air flow, which has the advantages of high efficiency, environmental protection, and energy saving.

The vacuum feeder is one of the important equipment in the pneumatic conveying system. It uses vacuum to suck materials out of the storage hopper and transport them to the destination through the conveying pipe.

The distance and height of pneumatic conveying depend on the material, the performance of the conveying equipment and the design of the conveying pipe. Generally speaking, the distance of pneumatic conveying can reach tens of meters or even hundreds of meters, and the height of conveying can also reach tens of meters or even higher.

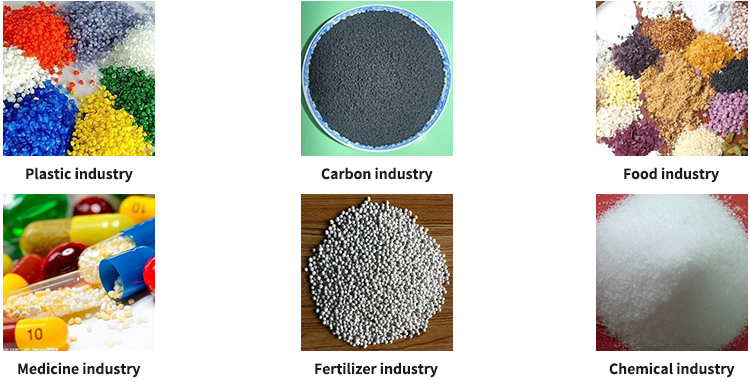

Pneumatic conveying is an efficient, environmentally friendly and energy-saving material conveying method, which is widely used in chemical, pharmaceutical, food and other industries.

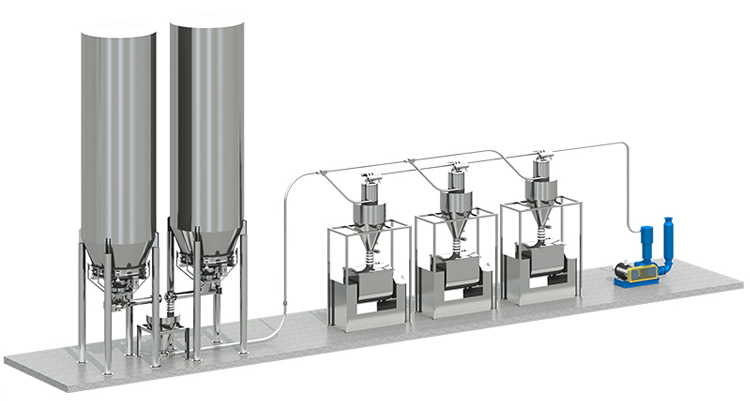

Implementation function:

The materials are stored in the silo, and discharged through discharger and screw conveyor. A hopper is set below, and then transported to the dough mixer through negative transport.

The hopper can be equipped with a weighing module, which becomes an incremental scale. By this, materials can be flexibly matched according to needs.

A weighing module can be installed on the feeder, and soft connection is adopted in the pipeline to achieve dynamic weighing. This mode is an incremental weighing mode, and it is a dynamic weighing mode. The disadvantage is the weighing accuracy cannot be guaranteed, and the conveying distance will also affect the weighing accuracy.

Another mode is to replace the butterfly valve at the outlet to a screw conveyor, and also install a weighing module to achieve a reduced weighing mode, which can ensure the weighing accuracy. The disadvantage is that the material needs to be stored in the hopper, and the feeding speed will be slightly slower.

Application industry