Vacuum feeder transfer system powder and granule feeding machine

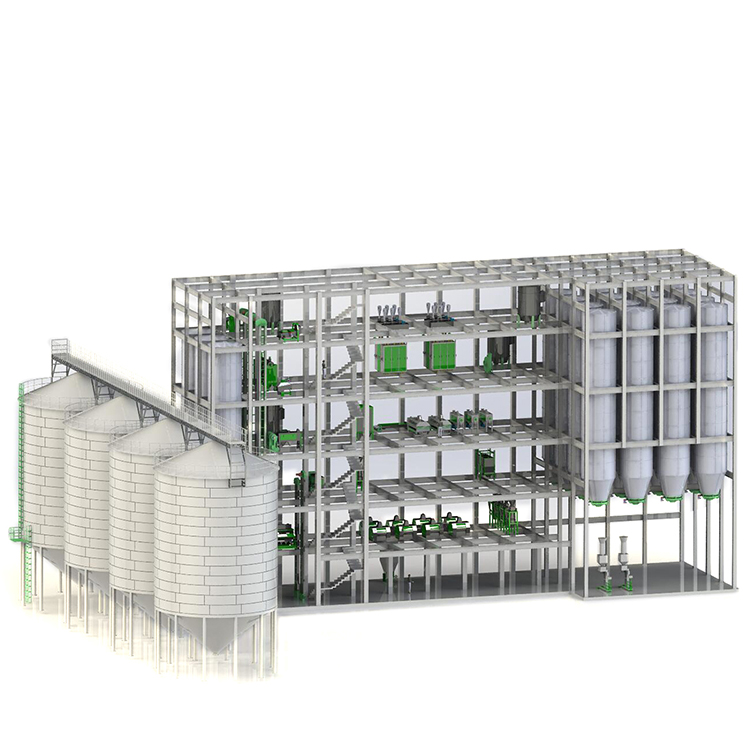

Pneumatic conveying is a method of conveying materials through air flow, which has the advantages of high efficiency, environmental protection, and energy saving.

The vacuum feeder is one of the important equipment in the pneumatic conveying system. It uses vacuum to suck materials out of the storage hopper and transport them to the destination through the conveying pipe.

The distance and height of pneumatic conveying depend on the material, the performance of the conveying equipment and the design of the conveying pipe. Generally speaking, the distance of pneumatic conveying can reach tens of meters or even hundreds of meters, and the height of conveying can also reach tens of meters or even higher.

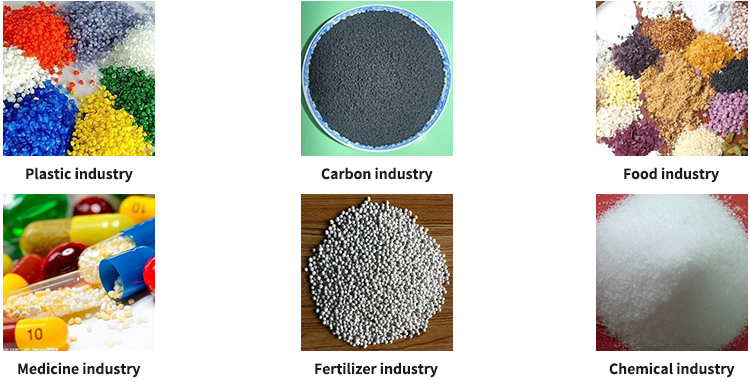

Pneumatic conveying is an efficient, environmentally friendly and energy-saving material conveying method, which is widely used in chemical, pharmaceutical, food and other industries.

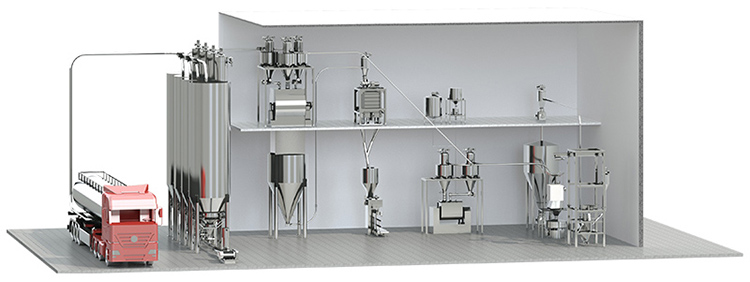

Implementation function

1. Powder from bulk trucks is blown into the bulk bin through Roots blower.

2. The ton bag unloader can realize bagged powder feeding, or direct manual feeding.

3. The powder after the vacuum feeder, bulk bin and tonnage bag unloader enters the mixer to mix and put into the temporary storage bin to realize the function of mixing powder..

4. The mixed powder enters the temporary storage bin, and then is sieved through a powder sifter, and then packed and divided by the packer.

5. The powder after the temporary storage bin and the ton bag unloader is sent to the dough mixer through the feeder. The upper liquid adding equipment can be proportioned according to needs, such as quantitative addition of salt water mixture, quantitative addition of oil, etc. .

This project can be customized according to customer needs.

Application industry