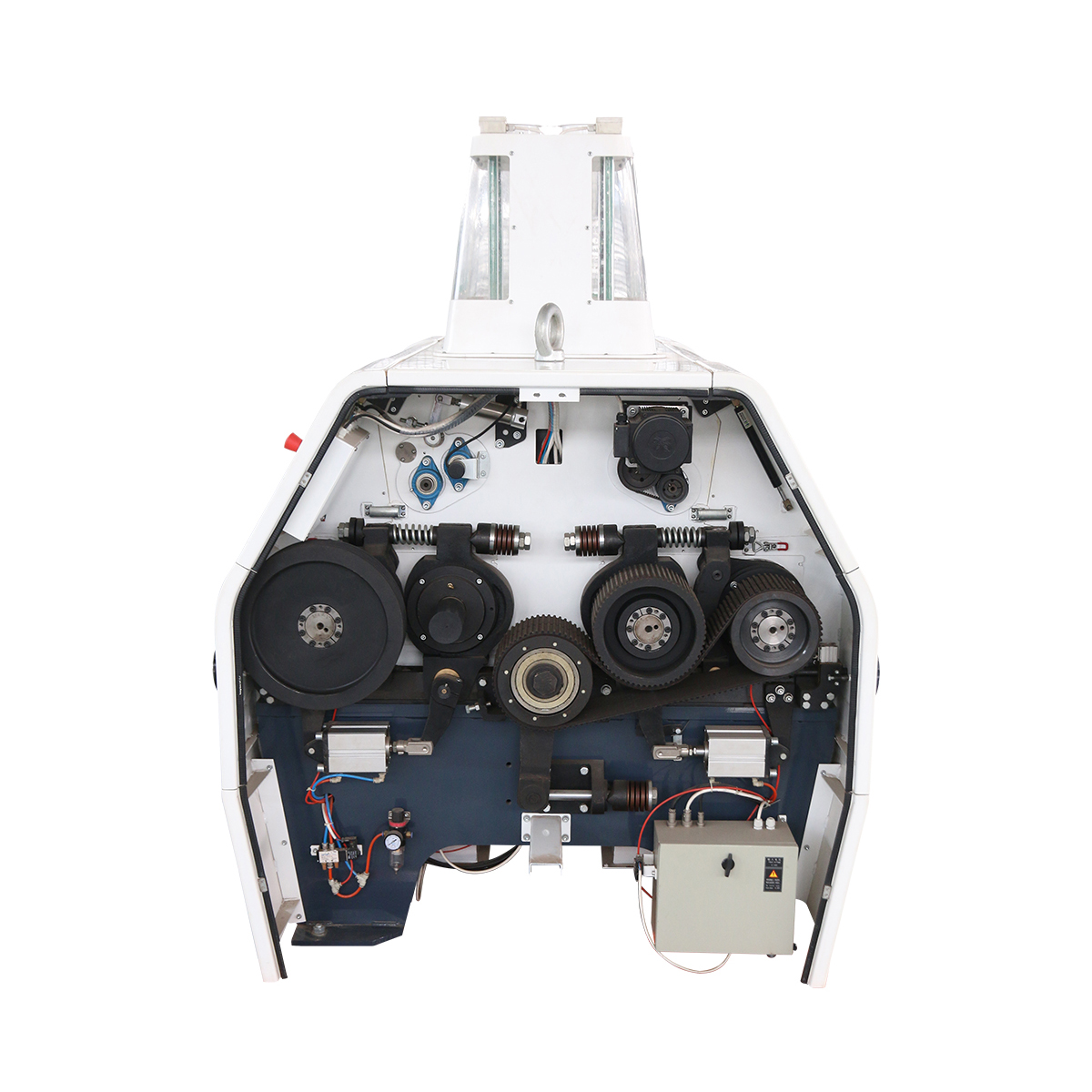

Vacuum Feeder

The vacuum feeder is a vacuum conveying equipment for powdery materials, granular materials, and powder-granular mixtures. The vacuum feeder can automatically convey various materials to the hoppers of bins, packer, injection molding machines, milling machine and other equipment. It can also directly transport mixed materials to the mixer, reducing the labor intensity of workers and solving the problem of dust spillage during feeding.

Features

Sealed conveying, no dust leakage, no cross-contamination;

Comply with GMP standards, meets CIP requirements, and can provide sterile grade products;

Modular design, nos dead corners, convenient assembily and disassembly, quick and easy cleaning;

Automatic control, simple and convenient operation;

No heat is generated during the working process, safe and explosion-proof;

No vibration, low noise, high efficiency and energy saving, low operation and maintenance costs.

Working principle

The vacuum feeder uses a vacuum pump to generate vacuum, and the negative pressure generated by the vacuum sucks the material from inlet. Then the air and materials are separated in the filter chamber of the separation container. The materials fall automatically due to gravity and are collected into the silo. When the silo is filled with materials, the vacuum pump automatically shuts down and the pressure in the conveying equipment reaches equilibrium. The discharge valve opens, and the material flows out through the discharge port and falls directly into the storage container. When discharging, the filter element is automatically cleaned by the blowback air bag. After unloading, the discharging chamber automatically closes and the entire conveying process starts again.

| Technical parameters | |||

| Model | DTSL320D | DTSL430D | DTSL530D |

| Height | 1.14m | 1.29m | 1.43m |

| Volume | 12.3L | 29.7L | 49.8L |

| Weight | 42kg | 50kg | 58kg |

| Inlet Diameter | Φ51mm | Φ63mm | Φ76mm |

| Outlet Diameter | Φ219mm | Φ219mm | Φ219mm |

| Air Consumption | 25L/Min | 32L/Min | 40L/Min |

| Capacity | 0.5-1.2T | 0.8-2.5T | 1.5-5T |

| Filters | Film coated filters/Carbon sintered filters/Stainless steel filters | ||

| Material Condition | Powdery materials/Granular materials | ||

| Material Temperature | (-10℃-70℃) | ||

| Material Moisture Content | Not more than 20% | ||

| Material Granular Size | 0.4um-3mm | ||

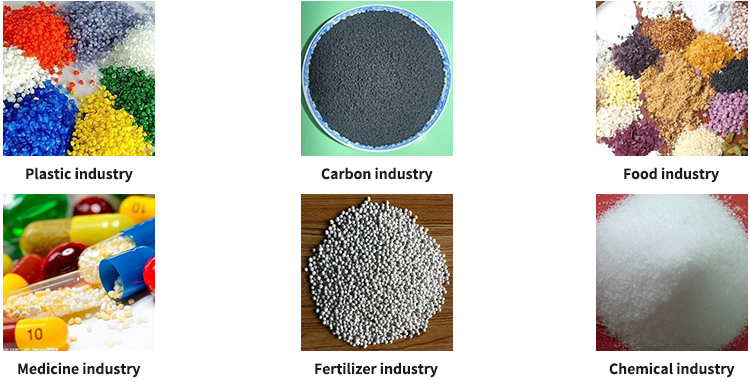

Application industry

Height