Professional Design Flour Mill Line - High Efficiency Indented Cylinder Separator – Chinatown

Professional Design Flour Mill Line - High Efficiency Indented Cylinder Separator – Chinatown Detail:

The optimal machine to kill the insect and its eggs

High-speed rotating, perfect impact result

For flour after the mill, before bin storage, or before packing

Insect destroyer for flour mill is applied before flour packing or it’s transferring to the bin, to effectively reduce the insects and their eggs. The high-speed rotating also leads to perfect impacting performance. Thus the flour storage endurance is greatly enhanced.

Specifications

Working principle

The material is fed into the machine from central inlet and is impacted fiercely by high-speed rotating rotor. Then the material leaves rotor in high linear speed rushing at pin and inner wall. During this process, the insects and the eggs are killed. Finally, the material is discharged from outlet.

Feature

1. The machine comes with a dynamically balanced rotor, ensuring smooth running.

2. Welded steel housing and anti-wear components are adopted for this equipment. The excellent durability leads to limited maintenance fees.

3. The impacting pins’ surfaces are thermally treated to achieve desirable wear resistance.

4. The round pins and square pins are optional for different passing properties and impact intensities.

5. Small area is needed for the installation of this flour-making equipment, and two installation types are optional. It can be mounted in the gravity conveying system or incorporated in the pneumatic conveying pipeline.

6. No floating dust will be generated and the repairing and operation are both very convenient.

7. A by-pass pipe and matching imported limit switch are installed. Thus when the machine stops, the mill system can continue to work.

8. The surface of the low carbon alloy steel pin, after being treated with nitriding and carbonization techniques, has become quite anti-wear.

Technical Parameters List

| ParameterType | Capacity | Power | Rotary Speed | Rotor diameter | Shape Size |

| t/h | KW | r/min | mm | L x W x H (mm) | |

| FSJZG-43 | 1.8 | 4 | 2900 | ф430 | 800x520x805 |

| 2.9 | 5.5 | 2900 | |||

| 4.7 | 7.5 | 2900 | |||

| FSJZG-51 | 4.5 | 15 | 2900 | ф510 | 800x690x850 |

| 6.2 | 18.5 | 2900 | |||

| 8.8 | 22 | 2900 | |||

| FSJZG-51D | 11-15 | 30 | 2900 | ф510 | 1081x800x850 |

| 15-18.5 | 37 | 2900 | |||

| 18.5-23 | 45 | 2900 |

Product Details

Rotary Pin

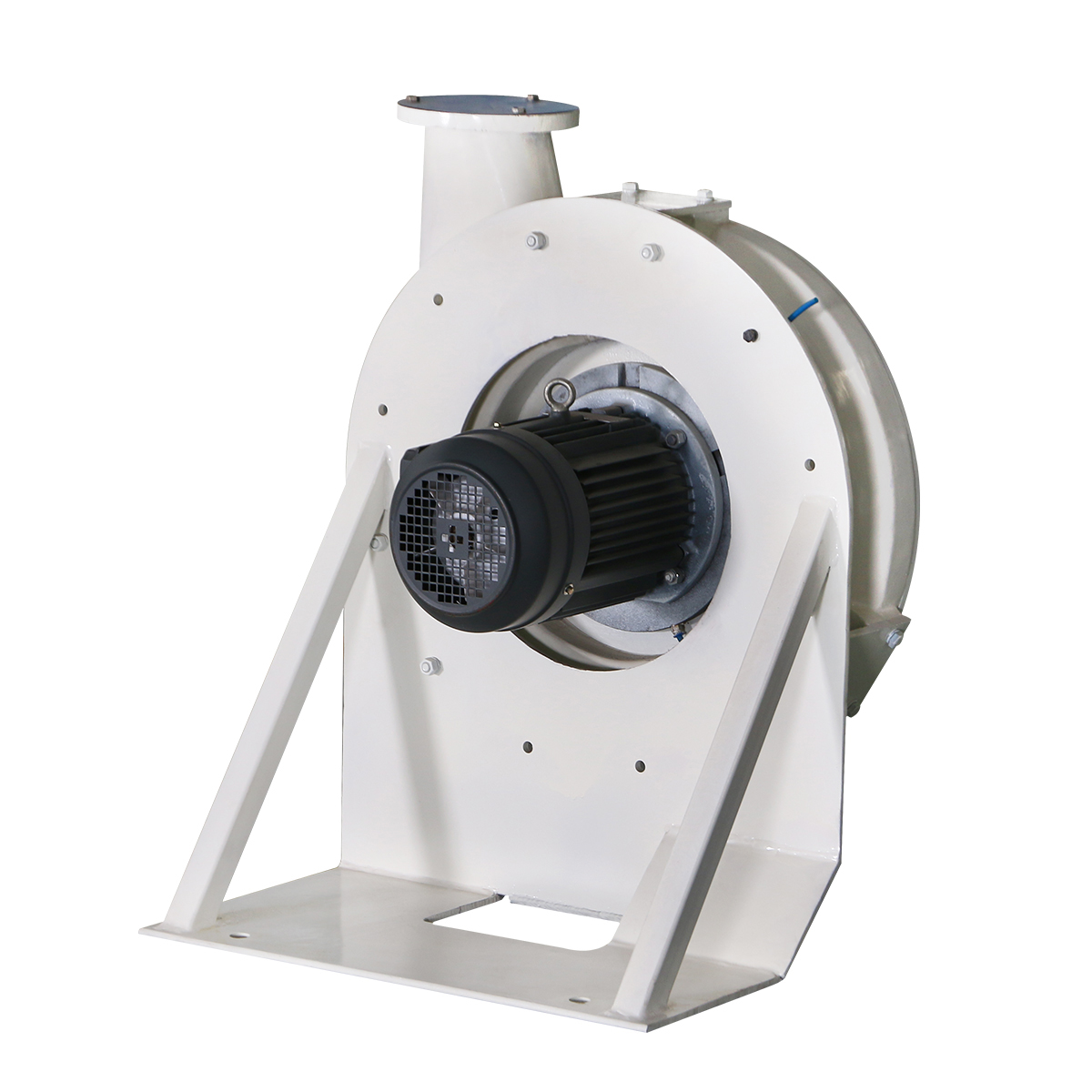

ABB Brand Motor

About Us

Product detail pictures:

Related Product Guide:

With a positive and progressive attitude to customer's interest, our enterprise continually improves our products excellent to meet the wants of customers and further focuses on safety, reliability, environmental requirements, and innovation of Professional Design Flour Mill Line - High Efficiency Indented Cylinder Separator – Chinatown , The product will supply to all over the world, such as: panama, Sao Paulo, Israel, During the 10 years of operating, our company always try our best to bring consumption satisfaction for user, built a brand name for ourselves and a solid position in the international market with major partners come from many countries such as Germany, Israel, Ukraine, United Kingdom, Italy, Argentina, France, Brazil, and so on. Last but not least, price of our products are very suitable and have fairly high competition with other companies.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!