-

Food powder pneumatic transport machine vacuum feeder transfer system

Pneumatic conveying is a method of conveying materials through air flow, which has the advantages of high efficiency, environmental protection, and energy saving.

-

Wheat powder air drive vacuum conveyor vacuum powder transport system

Pneumatic conveying is a method of conveying materials through air flow, which has the advantages of high efficiency, environmental protection, and energy saving.

-

Customized industrial vacuum powder suction feeder vacuum powder transport system

Pneumatic conveying is a method of conveying materials through air flow, which has the advantages of high efficiency, environmental protection, and energy saving.

-

Pneumatic vacuum feeder conveyor wheat flour powder vacuum conveyor feeder

Pneumatic conveying is a method of conveying materials through air flow, which has the advantages of high efficiency, environmental protection, and energy saving.

-

Vacuum feeder transfer system powder and granule feeding machine

Pneumatic conveying is a method of conveying materials through air flow, which has the advantages of high efficiency, environmental protection, and energy saving.

-

Flour Batch Scale

It/ PLC computer automatic flour batch scale is mainly used for proportioning and weighing of different materials, suitable for flour batching in the post-processing section of flour mills and feed mills batching. It is also widely used in quantitative automatic batching of powdery materials in various processing and production factories.

-

Inserted Jet Filter

This machine is used for silo roof dust removal, and small air volume single point dust removal.It is widely used in flour mills, warehouses and mechanized grain depots.

-

Jumbo Bag Unloading Machine

The jumbo bag unloading machine uses an electric hoist or forklift to lift the jumbo bag to the feeding port, press the bag, open the jumbo bag unloading port, and use a tapping device or vibration device to push the material into the lower hopper.

-

Manual Feeding Station

The manual feeding station adopts a new type of dust collector equipment and is equipped with a vibrator to assist in feeding, ensuring that there is no dust, smooth feeding, and no extravagant waste of raw materials throughout the entire feeding process, which can prevent material powder from flying everywhere.

-

Vacuum Feeder

The vacuum feeder is a vacuum conveying equipment for powdery materials, granular materials, and powder-granular mixtures.

-

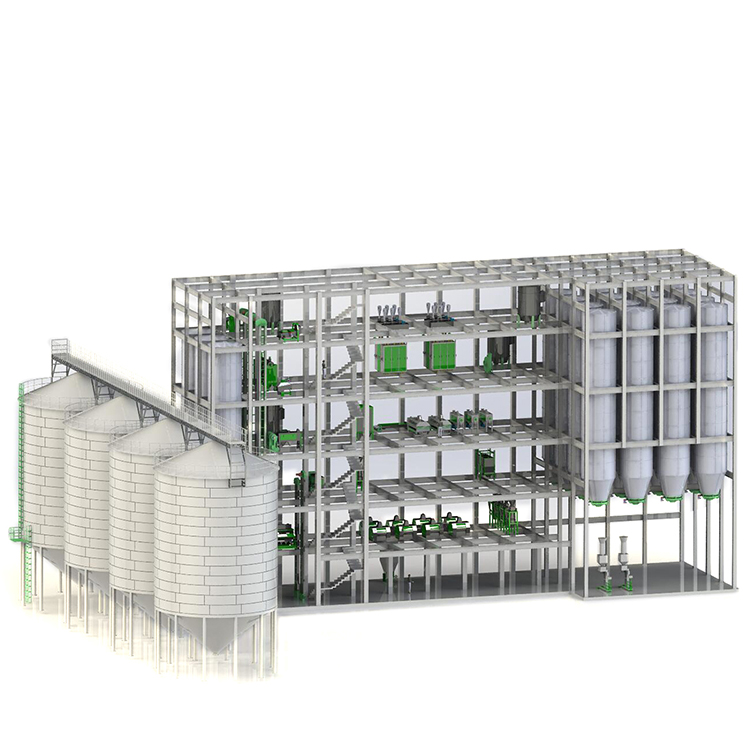

500 Ton Wheat Flour Mill Plant

These machines are mainly installed in reinforced concrete buildings or steel structural plants, which are generally 5 to 6 stories high (including the wheat silo, flour storage house, and flour blending house).

-

200 Ton Wheat Flour Mill Plant

Our flour milling solutions are mainly designed according to American wheat and Australian white hard wheat. When milling a single kind of wheat, the flour extraction rate is 76-79%, while the ash content is 0.54-0.62%. If two kinds of flour are produced, the flour extraction rate and ash content will be 45-50% and 0.42-0.54% for the F1 and 25-28% and 0.62-0.65% for the F2.