-

High-Quality Roots Blower Machine

Roots blower, is also referred to as air blower or roots supercharger. It consists of four major components, namely housing, impeller, and silencers at the inlet and outlet. The three-vane structure and reasonable inlet and outlet structure have directly led to the low vibration and low noise properties. This kind of blower can be used in a flour mill for positive pressure conveying.

-

TBHM Series Pulse Jet Filter

Tangent air inlet design can first separate bigger dust particles to reduce the load of the filters. It also can be made square shape according to requirements.

-

TDXZ Series High Quality Vibro Discharger

To discharge materials from a bin or silo without being choked by the vibration of the machine.

Installed under the dampened wheat bins, flour bins, and bran bins for the materials being discharged continuously. -

THFX Series Two Way Valve

The machine for changing the material conveying direction in a pneumatic conveying system. Widely used in a pneumatic conveying line of flour mill, feed mill, rice mill, and so on.

-

TLSS Wheat Flour Screw Conveyor

Our premium screw conveyor is suitable for conveying powder, granular, lumpish, fine- and coarse-grained materials such as coal, ash, cement, grain, and so on. The suitable material temperature should be less than 180℃. If the material is easy to get spoiled, or agglomerated, or the material is highly adhesive, it is not advisable to convey it on this machine.

-

TWJ Series Additive Micro Feeder

To make the addition of some micro-ingredients like starch and gluten more precise, we successfully developed the micro feeder. As a micro-dosing machine, it can be used for the production of vitamin combinations, additives, pre-mixing material, mixed feed, and so on. Besides, it is also suitable for industries like chemical engineering, medicine production, mining, etc.

-

Wheat Corn Grain Conveying Belt Conveyor

The conveying length of our belt conveyor ranges from 10m to 250m. The available belt speed is 0.8-4.5m/s. As a universal grain processing machine, this conveying machine has been widely used in the grain processing industry, power plant, ports and other occasions for conveying granule, powder, lumpish or bagged materials, such as grain, coal, mine, and so on.

-

200 Ton Maize Flour Mill Plant

CTCM-series Maize Flour Mill Plant can mill corn/maize, sorghum, soybean, wheat, and other materials. This CTCM-series Maize Flour Mill Plant adopts wind powerlifting, roll grinding, combining with sifting together, thus gaining the ability of high productivity, well powder lifting, no flying dust, low power consumption, easy to maintain, and other good functions.

-

120 Ton Maize Flour Mill Plant

CTCM-series Maize Flour Mill Plant can mill corn/maize, sorghum, soybean, wheat, and other materials. This CTCM-series Maize Flour Mill Plant adopts wind powerlifting, roll grinding, combining with sifting together, thus gaining the ability of high productivity, well powder lifting, no flying dust, low power consumption, easy to maintain, and other good functions.

-

60 Ton Maize Flour Mill Plant

CTCM-series Maize Flour Mill Plant can mill corn/maize, sorghum, soybean, wheat, and other materials. This CTCM-series Maize Flour Mill Plant adopts wind powerlifting, roll grinding, combining with sifting together, thus gaining the ability of high productivity, well powder lifting, no flying dust, low power consumption, easy to maintain, and other good functions.

-

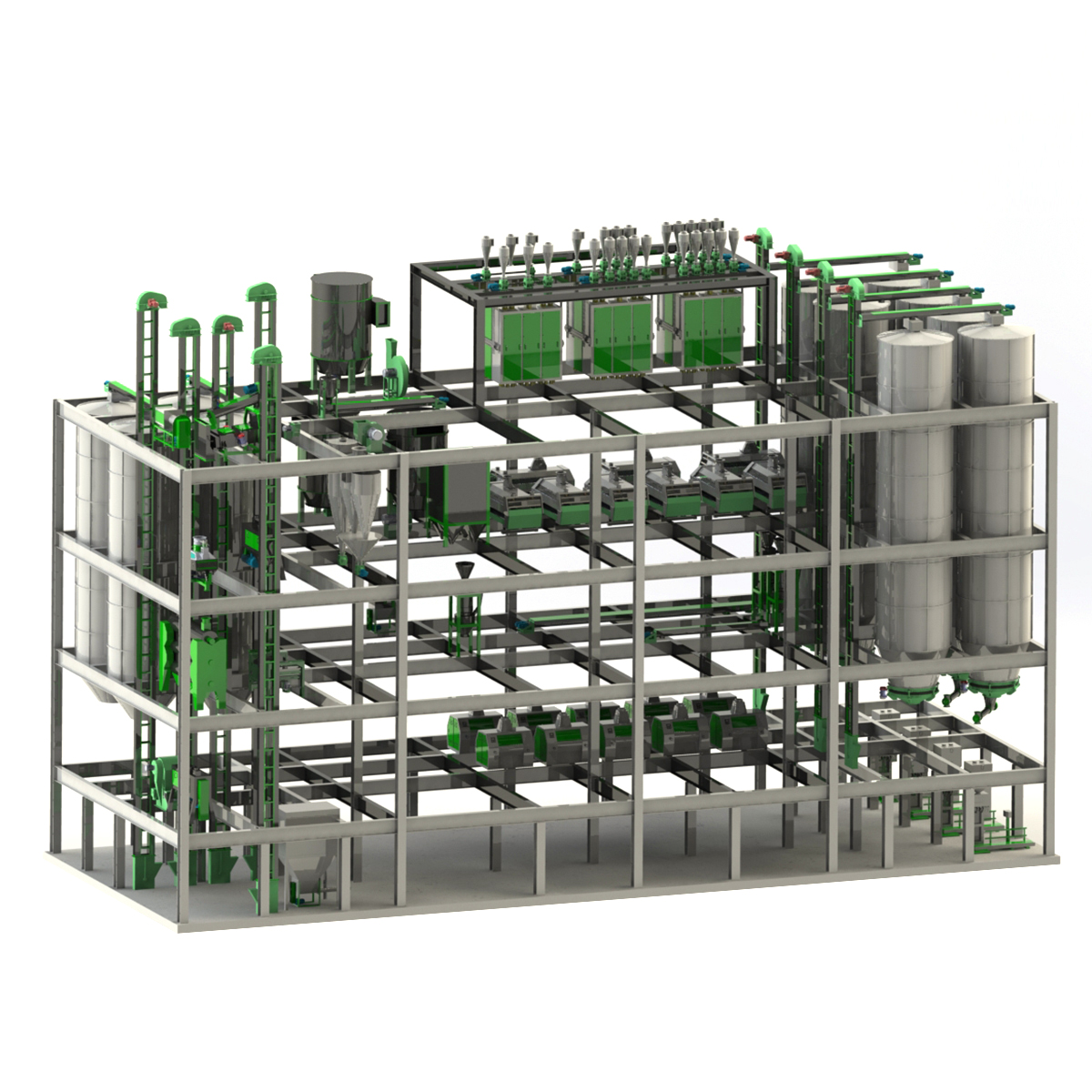

120 Ton Wheat Flour Mill Plant

These machines are mainly installed in reinforced concrete buildings or steel structural plants, which are generally 5 to 6 stories high (including the wheat silo, flour storage house, and flour blending house).

-

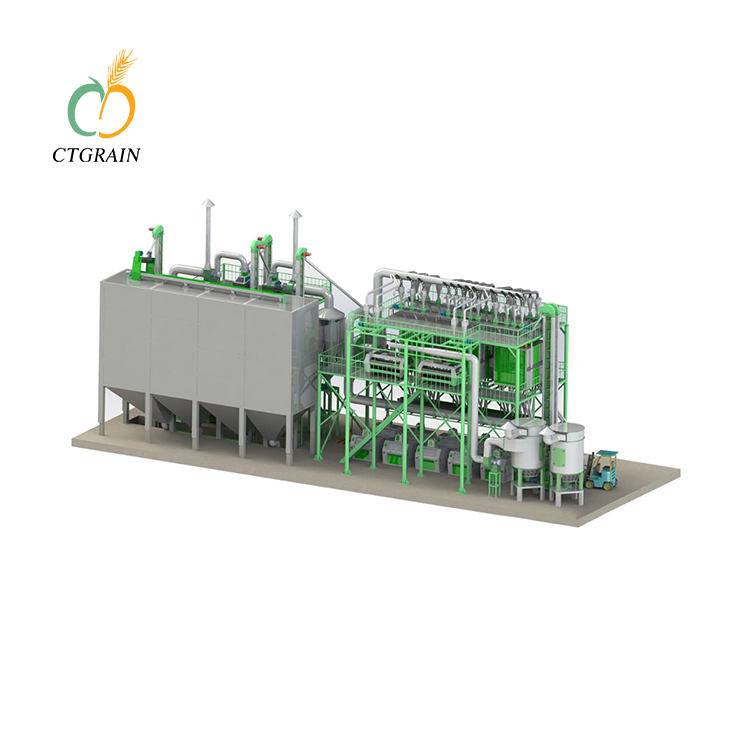

60 Ton Wheat Flour Mill Plant

Workshop height is relatively low to reduce customers’ investment. Optional PLC control systems can realize central control with a high degree of automation and make operation easier and more flexible. Enclosed ventilation can avoid dust spills to keep high sanitary working conditions. The whole mill can be compactly installed in a warehouse and designs can be customized as per different requirements.