-

Vacuum Feeder

The vacuum feeder is a vacuum conveying equipment for powdery materials, granular materials, and powder-granular mixtures.

-

Manual Feeding Station

The manual feeding station adopts a new type of dust collector equipment and is equipped with a vibrator to assist in feeding, ensuring that there is no dust, smooth feeding, and no extravagant waste of raw materials throughout the entire feeding process, which can prevent material powder from flying everywhere.

-

Flour Sifter Mono-Section Plansifter

To sift and classify material according to the particle size.

As a China flour sifter supplier, we have specially designed our mono-section plansifter. It has a compact structure, is lightweight, and easy installation and test running procedure. -

Jumbo Bag Unloading Machine

The jumbo bag unloading machine uses an electric hoist or forklift to lift the jumbo bag to the feeding port, press the bag, open the jumbo bag unloading port, and use a tapping device or vibration device to push the material into the lower hopper.

-

TSYZ Series Wheat Pressured Dampener

Our cost effective intensive dampener is a machine for controlling wheat moisture content during the wheat processing. After damping, the wheat could get even moisture distribution, improving the milling property and bran tenacity.

-

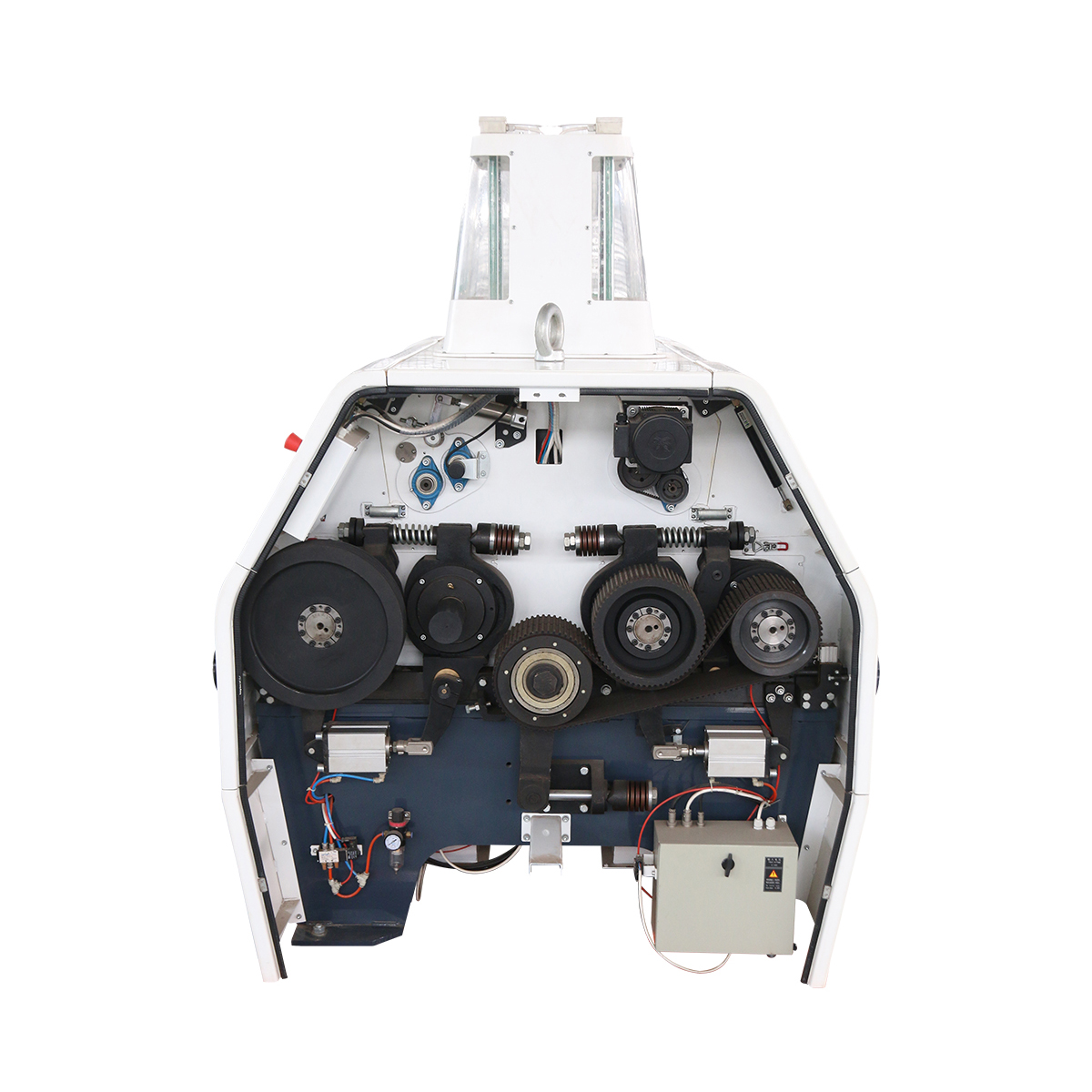

Wheat Maize Electrical Roller Mill

The machine for grain grinding

Widely used in Flour Mill, Corn Mill, Feed Mill and so on. -

Wheat Maize Pneumatic Roller Mill

The machine for grain grinding

The roller mill is an ideal grain milling machine for processing corn, wheat, durum wheat, rye, barley, buckwheat, sorghum and malt. The length of the milling roller is available in 500mm, 600mm, 800mm, 1000mm and 1250 mm. -

Wheat Mazie Grain Hammer Mill

The machine to crush granular materials

To crush grain like corn, sorghum, wheat, and other granular material

It is suitable for fine grinding in feed, medicine powder, grain, and food industries. -

Wheat Semolina Flour Plansifter Machine

The machine for sifting

The FSFG series plansifter is one of our core products developed on the basis of innovative ideas. It can efficiently sift and grade granular and pulverulent materials. As a premium flour sifting machine, it is suitable for the flour manufacturers who process wheat, rice, durum wheat, rye, oat, corn, buckwheat, and so on. In practice, this type of mill sifter is mainly used for processing grinded wheat and middle material sifting, also for flour check sifting. Different sieving designs suit different sifting passages and intermediate materials. -

Wheat Semolina Flour Purifier Machine

The machine for purifying

Our FQFD series purifier features with high capacity, high economical efficiency, high reliability and perfect design. It is suitable for purifying and classifying the grinded grain in modern flour mills for flour of soft wheat, durum wheat, and corn. -

Corn Maize MLT Series Degerminator

The machine for corn degerming

Equipped with several highly advanced techniques, comparing with similar machine from overseas, MLT series of degerminator prove to be best in peeling and de-germinating process. -

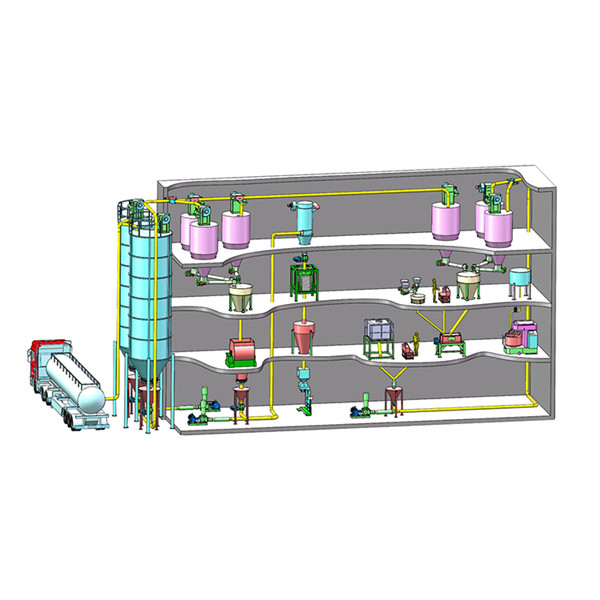

Auto Wheat Flour Blending Project

Millers buy wheat varieties with different characteristics to obtain various types of flour. As a result, it is difficult to maintain the quality of flour with a single wheat variety. In order to maintain a high-quality product at the end of the grinding process, millers must use different types of wheat of different quality when performing the blending process one of the significant steps of the grinding process.