Pneumatic vacuum feeder conveyor wheat flour powder vacuum conveyor feeder

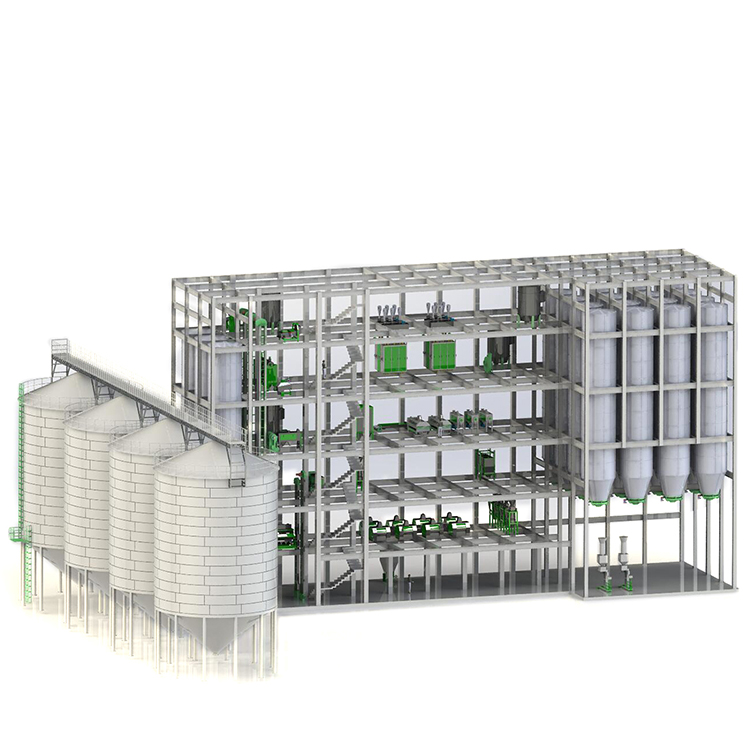

Pneumatic conveying is a method of conveying materials through air flow, which has the advantages of high efficiency, environmental protection, and energy saving.

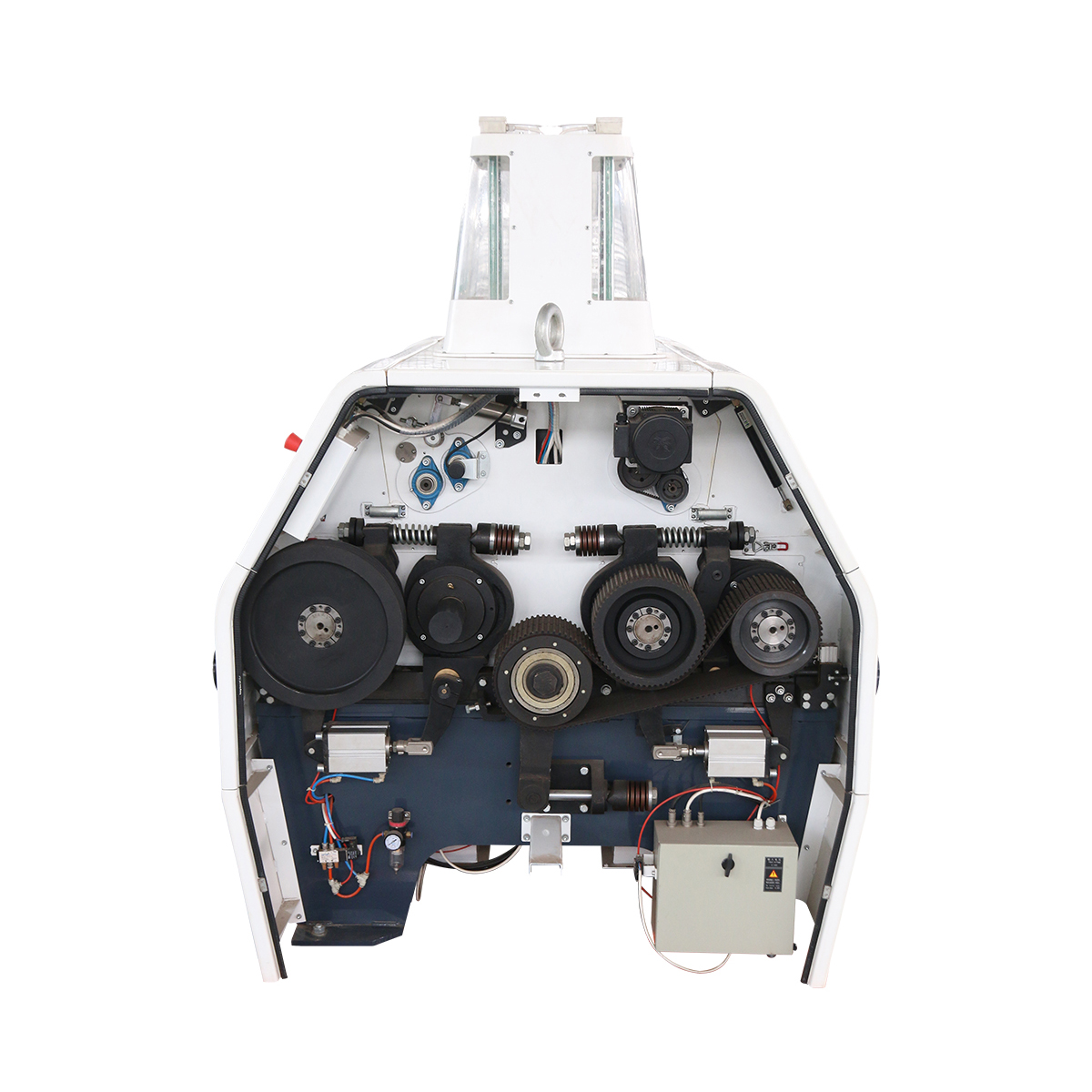

The vacuum feeder is one of the important equipment in the pneumatic conveying system. It uses vacuum to suck materials out of the storage hopper and transport them to the destination through the conveying pipe.

The distance and height of pneumatic conveying depend on the material, the performance of the conveying equipment and the design of the conveying pipe. Generally speaking, the distance of pneumatic conveying can reach tens of meters or even hundreds of meters, and the height of conveying can also reach tens of meters or even higher.

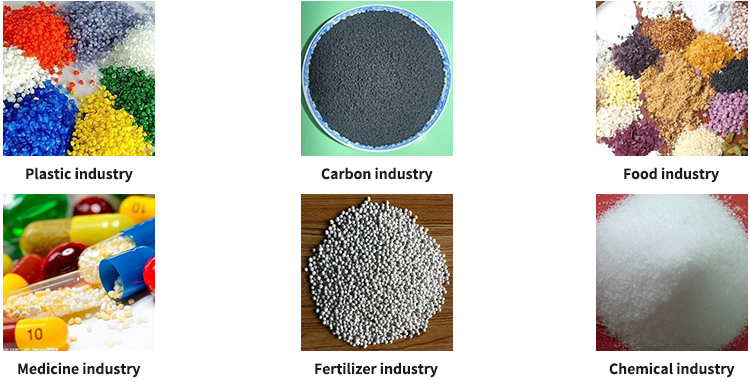

Pneumatic conveying is an efficient, environmentally friendly and energy-saving material conveying method, which is widely used in chemical, pharmaceutical, food and other industries.

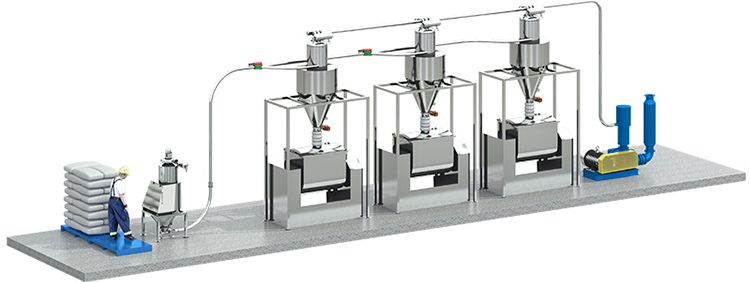

Manual quantitative feeding

Workers need to feed materials quantitatively according to the actual usage of the dough mixer. For example, if each batch requires 100kg of materials, then workers need to pour 4 bags of 25kg of materials into the feeding station. They can also proportion and add ingredients according to actual needs.

This project uses one roots blower equipped with three sets of vacuum feeders. This vacuum feeder is a non-standard model, and the capacity of the buffer hopper can be customized as needed.

The materials can be stored in the hopper. When the dough mixer needs materials, open the butterfly valve, then the materials can quickly fall into the dough mixer.

The use of manual feeding station can effectively solve the dust generated during manual dumping.

Application industry