-

Common cleaning methods in wheat flour milling processing

In the flour milling process, the wheat needs to be cleaned up first. The cleaning methods are generally divided into two types: 1. Dry cleaning processing The dry cleaning processing mainly includes screening, stone removal, width selection, air separation, and magnetic separation. At present, ...Read more -

Common equipment for wheat cleaning in flour mill processing

Considering different characteristics of the material, different machines are adopted for cleaning purposes: Based on different sizes: Pre-Cleaning Separator, Rotary Separator, Vibro Separator. Based on different specific gravity: Gravity Destoner. Based on different floating speeds: Aspiration ...Read more -

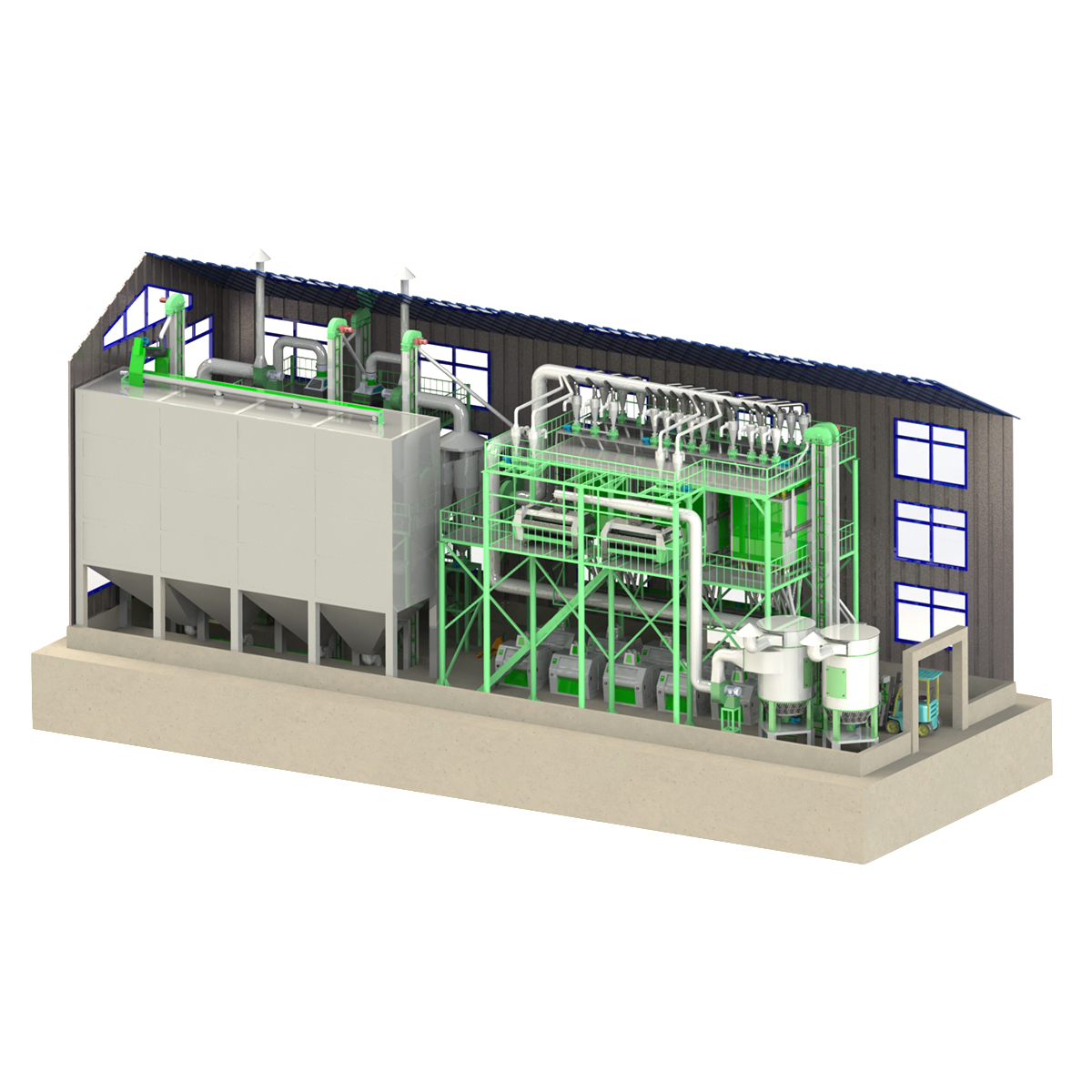

120-ton per day wheat Flour processing project

The flour processing is to grind the wheat into flour based on different quality standards and uses. The production line is divided into four sections from raw grain to finished product. In the silo section, the cleaning section, the milling section, and the blending section, the detailed proces...Read more -

Flour processing technology – wheat mixing

Applicable wheat blending is very important in wheat flour processing. In order to ensure consistent wheat performance, the production process is relatively stable, and the quality of the same grade of flour of the same variety produced in different batches is as consistent as possible. ...Read more -

What are the wheat cleaning steps before grinding?

1. First remove all large impurities and some light impurities through the vibrating separator and the aspiration channel. 2. The wheat is passed through a tubular magnetic separator to remove magnetic metal. 3. wheat through the horizontal wheat scourer to remove mud, awn of wheat, and other im...Read more -

Flour milling machine classification in wheat flour mill plant

There are many types of flour milling machines currently in use, and there are several types according to different classification methods: The length of the grinding roller is divided into three types: large, medium, and small. The roll length of large roller mills is generally 1500, 1250, 1000...Read more -

The roller mill used in grain processing

For the same series of flour milling machine, flour from two sets of mills are better than the flour milled by one group mill. In the process of milling, the two sets of mills have different functions, one is for grinding the bran of wheat, and another one is for grinding the core of wheat. If o...Read more -

Rotary separator in flour mill processing

Rotary separator in flour mill processing has the advantages of reasonable design, simple structure, stable operation, fully enclosed structure, no dust, no anti-blocking, anti-adhesive net, and so on. In particular, the screening effect of materials with strong hygroscopicity, high viscosity, e...Read more -

Effect of material moisture on plansifter

Plansifter is one of the main equipment in flour milling processing. Its operation status not only affects the progress of the milling process but also affects the quality of the product. In the actual production process, the proper material moisture is one of the conditions for ensuring the nor...Read more -

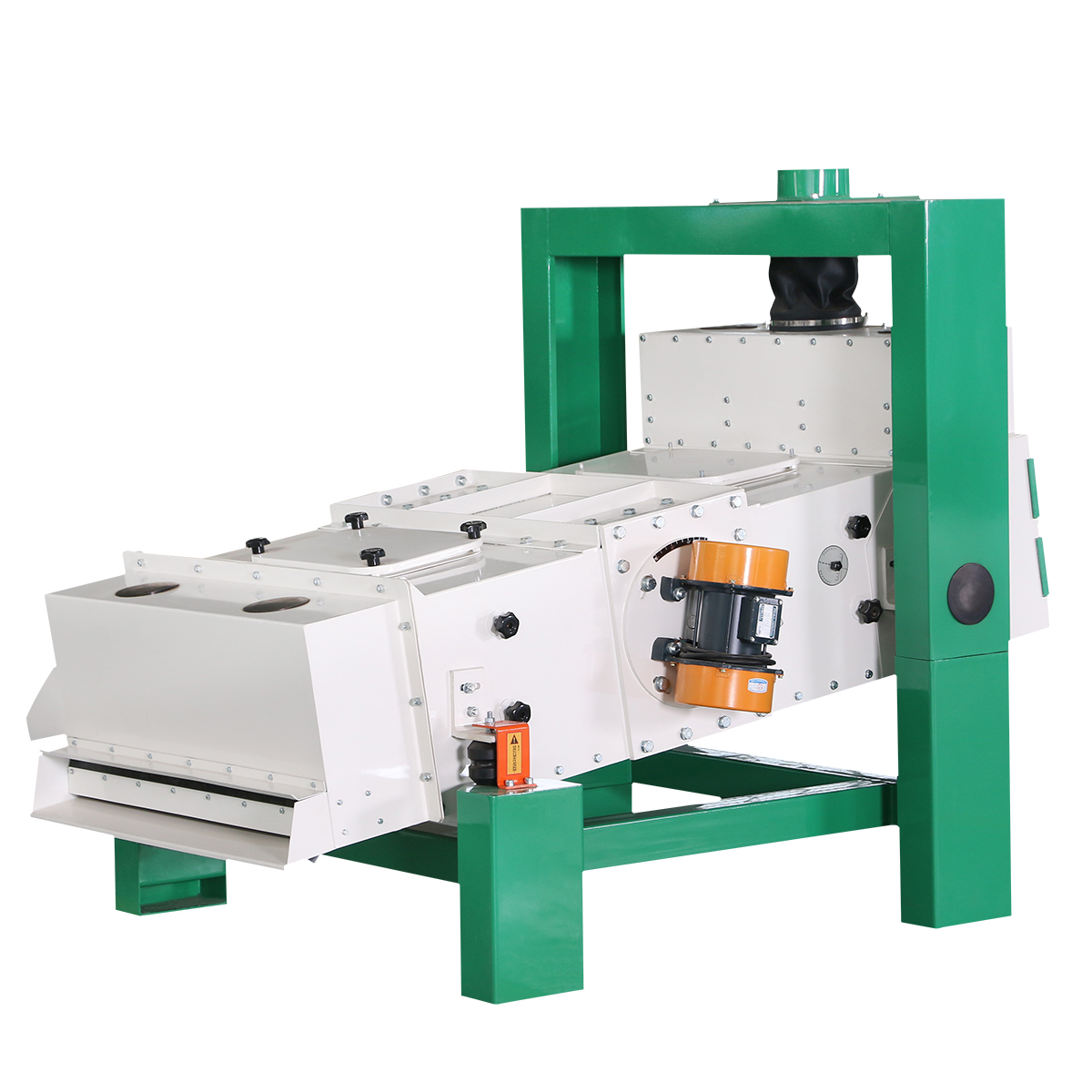

Vibrating separator in wheat flour mill plant

TQLZ series vibrating separator is a commonly used equipment for wheat flour mill plant. It is widely used in maize flour mills, feed mills, seed cleaning plants, food processing, and other industries. It has the characteristics of high screening efficiency, low vibration noise, sturdy and durab...Read more -

Gravity destoner machine in grain processing

The gravity destoner machine is common equipment in the grain processing plant. It is based on the difference in the gravity and suspension speed of wheat and impurities. It promotes the separation of wheat from stones, dust, heavy wheat, and light wheat by the action of upward airflow. And then...Read more -

Roots blower installation precautions in wheat flour mill plant

1. The roots blower should not be installed in places where people often come in and out, to prevent injury and burns. 2. The roots blower should not be installed in a place prone to flammable, explosive, and corrosive gases, to prevent accidents such as fire and poisoning. 3. According to the d...Read more