-

Wheat corn grain conveying belt conveyor

The belt conveyor is a kind of friction-driven machinery that transports materials in a continuous manner. It is mainly composed of a frame, conveyor belt, idler, roller, tensioning device, transmission device, etc. It can transfer materials from the initial feeding point to the final unloading ...Read more -

How to select a seed cleaning machine?

Seed cleaning is the first step in seed processing. Due to the variety of impurities in the seeds, proper machinery should be selected for cleaning. According to the different properties, it can be divided into large impurities and small impurities according to the geometric dimensions; Accordin...Read more -

Precautions For Use Of Destoner Machine

Precautions for use of destoner machine: Before starting the destoner machine, check whether there is any foreign materials on the screen surface and the fan, whether the fasteners are loose, and turn the belt pulley by hand. If there is no abnormal sound, it can be started. During normal operat...Read more -

Wheat Flour Grainding Process

The main function of grinding is to break wheat grains. The grinding process is divided into skin grinding, slag grinding, and core grinding. 1. Peeling mill is the process of breaking wheat grains and separating endosperm. After the first process, the wheat grains are screened and separated int...Read more -

Wheat Moisture Regulation In Flour Mill Plant

As the moisture content and physical properties of wheat grains from different varieties and regions are different, some are dry and hard, and some are wet and soft. After cleaning, the wheat grains must also be adjusted for moisture, that is, the wheat grains with high moisture content should b...Read more -

Flour Mill Equipment: Pneumatic Slide Gate

The pneumatic slide gate is combineted high-quality motor and switch cylinder. and the closing opening speed is extremely fast, the good stability , convenient operation. In the flour processing mill, it can be matched with a chain conveyor or a screw conveyor to achieve the purpose of controlli...Read more -

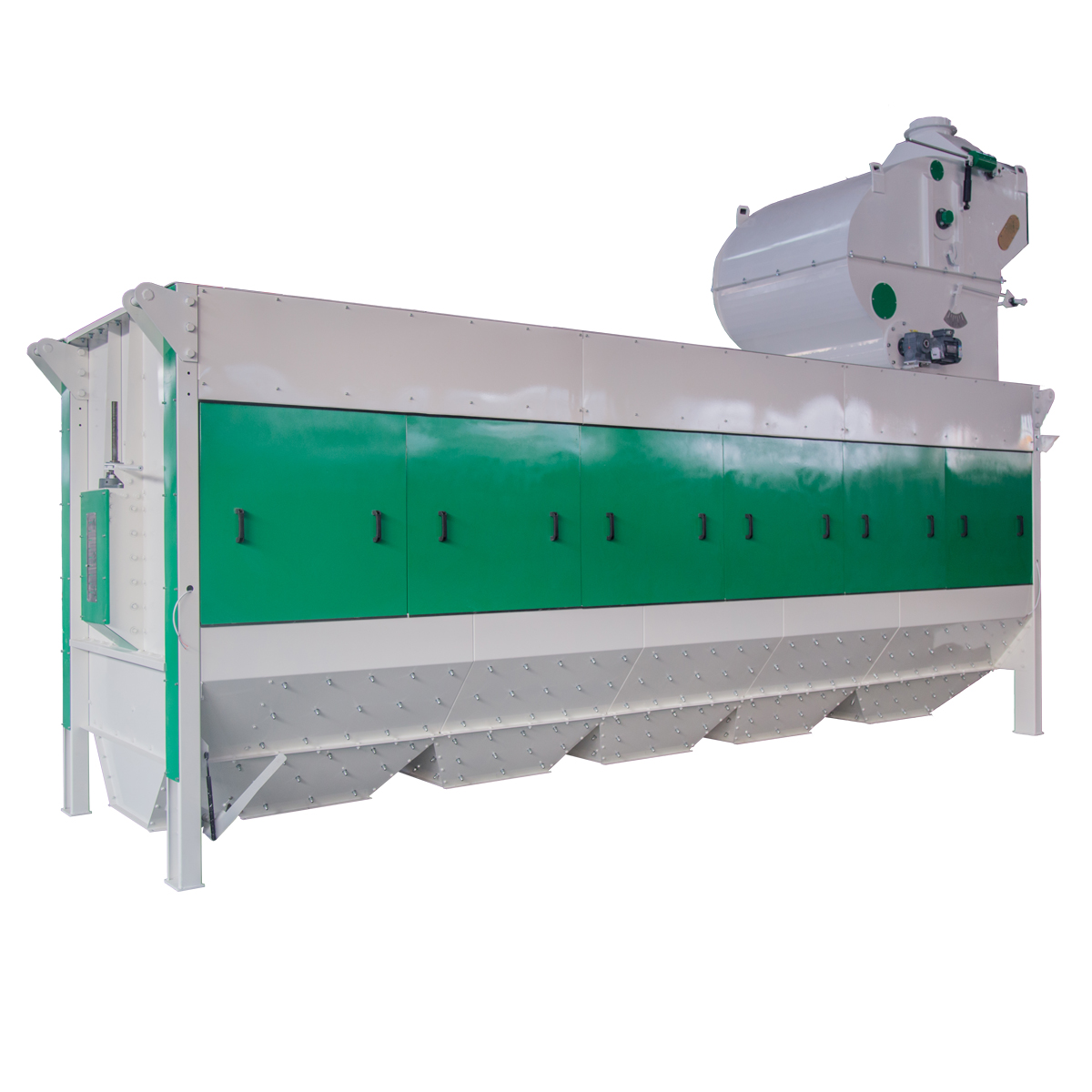

Flour Mill Equipment: Low Pressure Jet Filter

TBLM series Low Pressure Jet Filter are widely used in flour mill, grain and oil, and food processing plant. It is used to remove dust from the air. When the dust-containing air enters the tank, large particles of dust fall into the hopper along the wall of the cylinder, and small particles of d...Read more -

Wheat flour mill cleaning section technology

1. The wheat discharge accurately measures the flow of the wheat out of the warehouse, and measures the wheat blending for different varieties of wheat according to the demand. 2. Screening to remove large impurities (foreign grains, mud lumps) and small impurities (lime soil, broken seeds); 3. ...Read more -

Preliminary Cleaning Process In Flour Mill Plant

A. The accepted wheat must meet certain standards, such as moisture content, bulk density and impurities must meet the requirements of the corresponding grade of raw grain. B. The preliminary cleaning remove the large impurities, bricks, stones, ropes in wheat. C. Raw wheat cleaning removes larg...Read more -

Cleaning Standard Of Wheat In Flour Mill Plant

(1) After treatment, it is basically free of large impurities, small impurities and lime soil not more than 0.1% (2) After treatment, there is basically no magnetic metal. (3) Unqualified wheat shall be re treated before entering the next process. (4) The primary water regulation of wheat is car...Read more -

Flour Mill Equipment: positive pressure airlock and negative pressure airlock

Positive pressure airlock and negative pressure airlock are the main auxiliary equipment in a flour mill. During the material conveying process, it can evenly feed, and the upper and lower air pressure are blocked off to play a sealing role so that the air ventilation system works normally. It i...Read more -

Flour Mill Equipment-Two way valve

The main equipment of the pneumatic conveying system includes an air source device–Roots blower, a feeding device–Positive pressure airlock and Negative pressure airlock, pipeline conversion device–Two-way valve. The system has been used in various field factories such as flour...Read more