New Fashion Design for Wheat Processing Machine - 60 Ton Wheat Flour Mill Plant – Chinatown

New Fashion Design for Wheat Processing Machine - 60 Ton Wheat Flour Mill Plant – Chinatown Detail:

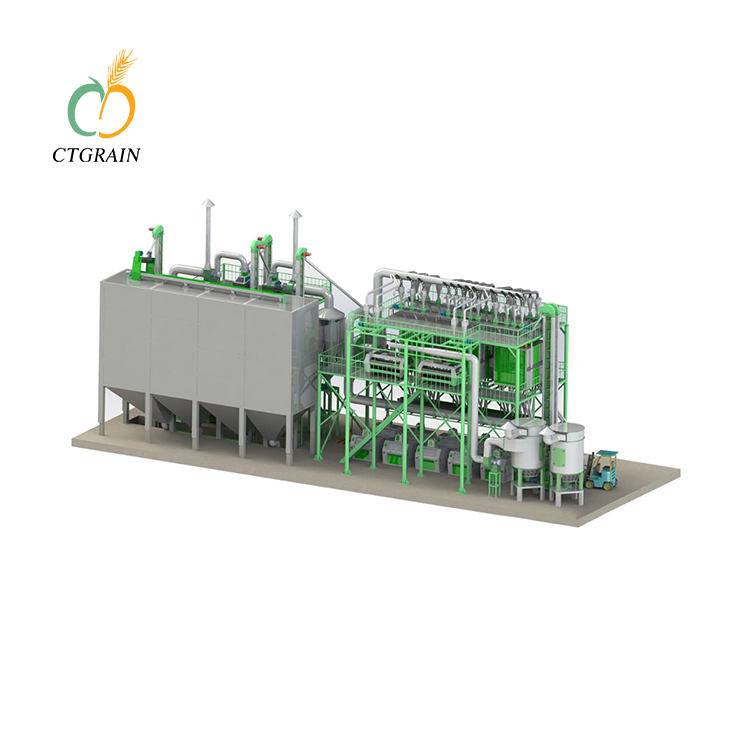

Wheat flour mill plant is designed and installed together with the steel structure support. The main support structure is made of three levels: the roller mills are located on the ground floor, the sifters are installed on the first floor, the cyclones and pneumatic pipes are on the second floor.

Workshop height is relatively low to reduce customers’ investment. Optional PLC control systems can realize central control with a high degree of automation and make operation easier and more flexible. Enclosed ventilation can avoid dust spills to keep high sanitary working conditions. The whole mill can be compactly installed in a warehouse and designs can be customized as per different requirements.

| Model | CTWM-60 |

| Capacity(t/24h) | 60TPD |

| Roller Mill Model | Manual |

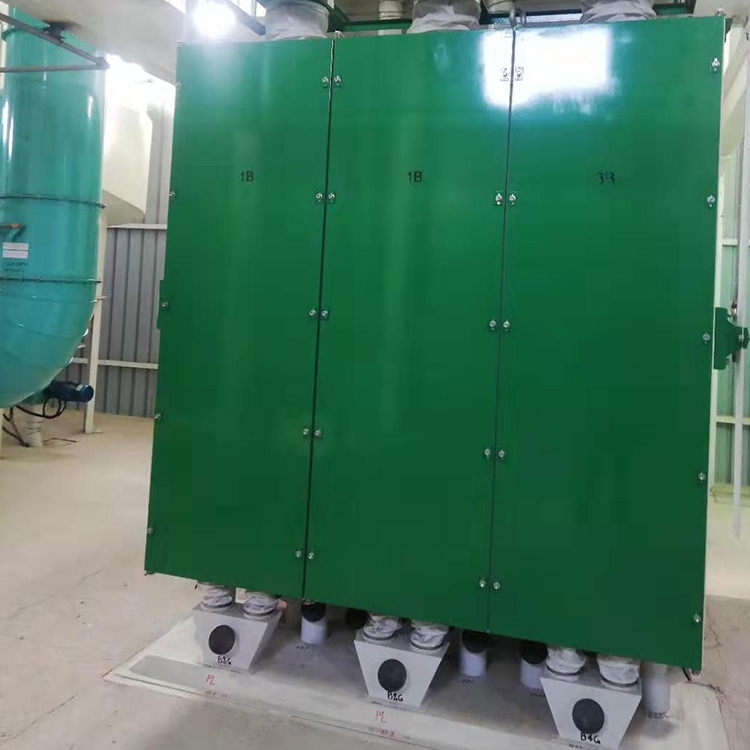

| Sifter Model | Twin sifter |

| Cleaning Flow Sheet | 3-sifting, 2-scrouring, 2-destoning, 1-washing |

| Mill Flow Sheet | 4-breaking, 5-reducing, 1T |

| Total Power(kw) | 220 |

| Space(LxWxH) | 35x8x11m |

Cleaning Section

In the cleaning section, we adopt drying-type cleaning technology. It normally includes 2 times sifting, 2 times scouring, 2 times de-stoning, one time purifying, 4 times aspiration, 1 to 2 times dampening, 3 times magnetic separation, and so on. In the cleaning section, there are several aspiration systems that can reduce the dust spray-out from the machine and keep a good working environment. This is a complicated thorough flow sheet that can remove most of the coarse offal, middle size offal, and fine offal in the wheat.

Milling Section

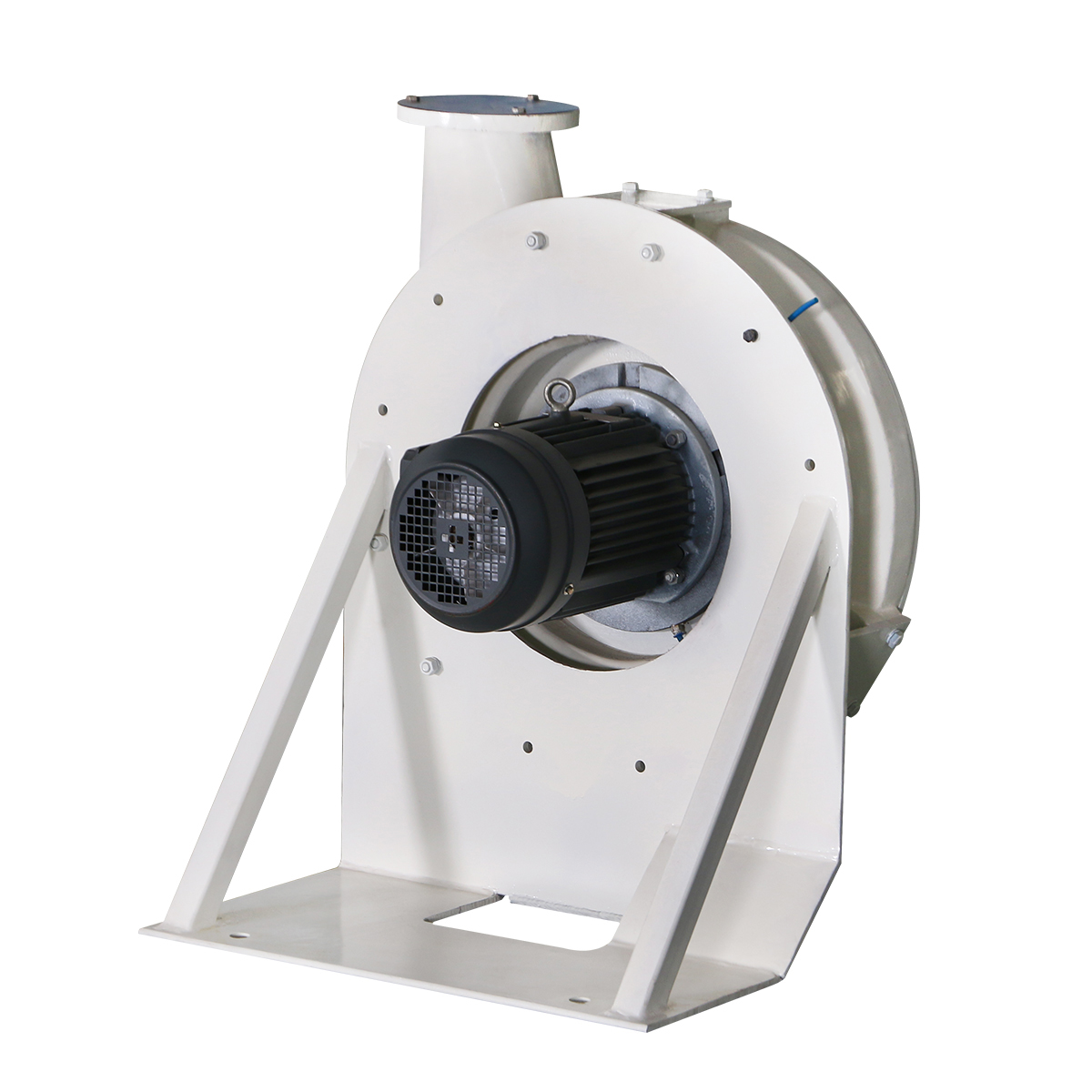

In the milling section, there are four types of systems to mill the wheat to flour. They are the 4-Break system, 7-Reduction system,1-Semolina system, and 1-Tail system. The whole design will insure less bran is mixed into the bran and the flour yield is maximized. Because of the well-designed pneumatic lifting system, the whole mill material is transferred by a High-pressure fan. The milling room will be clean and sanitary for aspiration adoption.

Flour Blending Section

The flour blending system mainly consists of a pneumatic conveying system, bulk flour storage system, blending system, and final flour discharging system. It is the most perfect and efficient way to produce tailored flour and keep the stability of flour quality. For this 200TPD flour mill packing and blending system, there are 3 flour storage bins. The flour in storage bins is blown into 3 flour packing bins and packed finally.

Packing Section

The packing machine has features of high measuring accuracy, fastpacking speed, reliable and stable working. It can weigh and count automatically, and it can accumulate weight. The packing machine has the function of fault self-diagnosis. The packing machine is with sealed type bag-clamping mechanism, which can prevent material from leaking out.The packing specification includes 1-5kg,2.5-10kg,20-25kg,30-50kg.The clients can choose different packing specifications according to requirements.

Electrical Control And Management

We will supply an electrical control cabinet, signal cable, cable trays and cable ladders, and other electrical installation parts. The substation and motor power cable are not included except customer especially required. PLC control system is an optional choice for customers. In a PLC control system, all the machinery is controlled by Programmed Logical Controller which can ensure the machinery runs stably and fluently. The system will make some judgments and do reactions accordingly when any machine is at fault or stopped abnormally. At the same time, it will alarm and remind the operator to settle the faults.

| Technical Specification: | |

|

Item |

Description |

|

1 |

Cleaning flow sheet: 3-sifting 2-scouring 2-destoning 1-dampening |

|

2 |

Flour mill installation area: Length x Width x Height = 46 x 10 x 11 meters |

|

3 |

Installation Power: 392Kw. |

|

4 |

Water consumption: 0.25T/H |

|

5 |

Operator needed : 4-6 person |

|

6 |

Flour quality: If producing straight flour, the yield is 75%, ash content is 0.54-0.62% (as is basis). If producing 2 grades of flour, the extraction rate of Grade 1 flour is 50%, and with ash content 0.43-0.54%; and the extraction rate of Grade 2 flour is 28%, with ash content 0.62-0.65%. The ash content above is on wet basis. This data is based on the wheat quality which is same or better than grade 2 from America or Australia. |

About Us

Thus far we have provided our products and service to customers from over 60 countries, including Australia, Germany, Britain, Argentina, Peru, Thailand, Tanzania, South Africa, and so on. etc.

FAQ

1. Q: Can the wheat flour mill machine also process maize?

A: No, it is because the maize and wheat Physical Characteristics are different, like the shape, and the hardness, all are different, and the final product flour size is also different. You can buy our Maize flour mill plant.

2. Q: Can the wheat flour milling plant pack different bags?

A: Yes,the packing machine can pack 1kg-5kg;5kg-20kg,20-50kg bags.

3. Q: Can the wheat flour mill machine running with Generator?

A: Yes, the wheat flour mill line can run with Generator.

4. Q: Are you the manufacturer?

A: Yes, We are a professional flour milling machine manufacturer.

5. Q: Will you help to install the machines?

A: Yes, our engineers can indicate installation, test running, and training of local operators. Engineers available to service machinery overseas after-sales Service

6. Q: What’s the warranty time?

A: Our warranty time is 12 months, so you can trust us and the quality of our machine.

Why choose us

Our company is a professional manufacturer of wheat flour mill plants and maize mill plants with more than 24 years of experience. A manufacturing factory of 15000 square meters. Our maize mill plant and wheat flour mill plant have passed ISO SGS CE certifications.

Product detail pictures:

Related Product Guide:

We insist on offering high-quality creation with superior business enterprise concept, honest revenue plus the greatest and fast service. it will bring you not only the high quality solution and huge profit, but essentially the most significant is usually to occupy the endless market for New Fashion Design for Wheat Processing Machine - 60 Ton Wheat Flour Mill Plant – Chinatown , The product will supply to all over the world, such as: Argentina, Anguilla, Thailand, We provide OEM services and replacement parts to meet the varying needs of our customers. We give competitive price for quality solutions and we are going to make certain your shipment is handled quickly by our logistics department. We sincerely hope to have the opportunity to meet with you and see how we can help you further your own business.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.