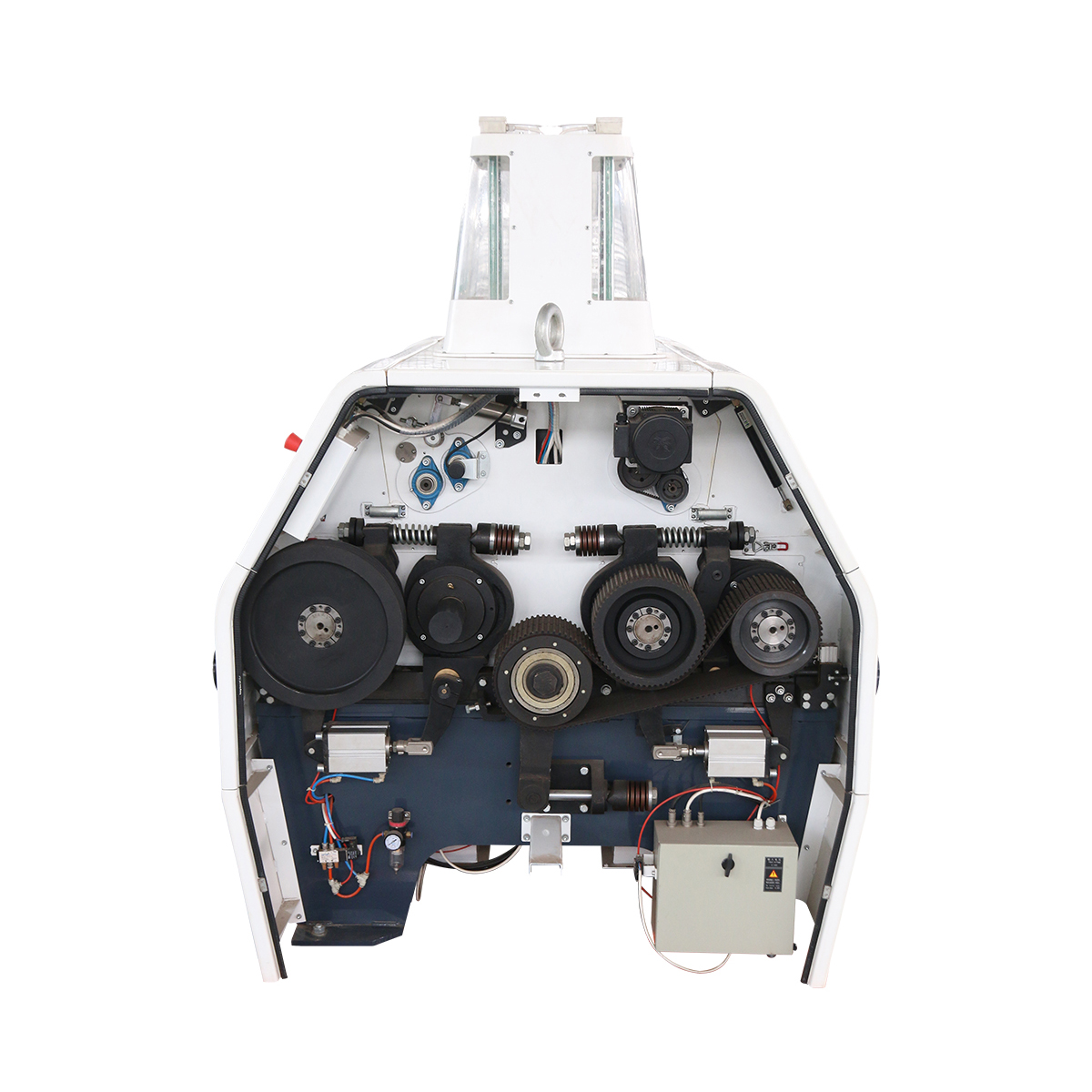

Manual Feeding Station

The manual feeding station adopts a new type of dust collector equipment and is equipped with a vibrator to assist in feeding, ensuring that there is no dust, smooth feeding, and no extravagant waste of raw materials throughout the entire feeding process, which can prevent material powder from flying everywhere. When the material is unpacked and poured into the next process, it only needs to be manually unpacked and directly put into the system. The material passes through a vibrating screen (safety screen), which can intercept large blocks of material and foreign objects, thereby ensuring that the particles meet the required granular discharge. It consists of feeding platform, unloading bin, main system, vibrating screen, etc. It can also be made without vibrating screen according to customer’s requirements.

Features

·Solve the problem of dust overflow, reduce environmental pollution and harm to human health.

·Low operational difficulty, reduced labor intensity, and quick to operate.

·It can be connected to positive/negative pressure conveying to supply materials for the production line.

·It can be flexibly customized to the working conditions and requirements of the customers.

| Technical Parameter List | ||||||

| Model | Dust Removal Fan | Vibrating Machine | Screen Diameter | Dust Filter | Machine Material | Processing Capacity |

| (kw) | (kw) | (mm) | ||||

| DTTS-6 | 1.5 | 0.12×1 | 560 | Polyurethane

Filters |

SUS304、

SUS316L |

60-180 bags/h

(25-50kgs/bag) |

| DTTS-8 | 1.5 | 0.12×2 | 760 | |||

| DTTS-10 | 2.2 | 0.25×2 | 930 | |||

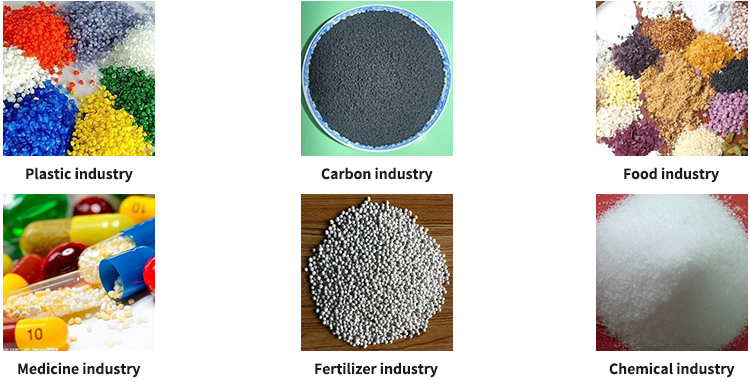

Application industry