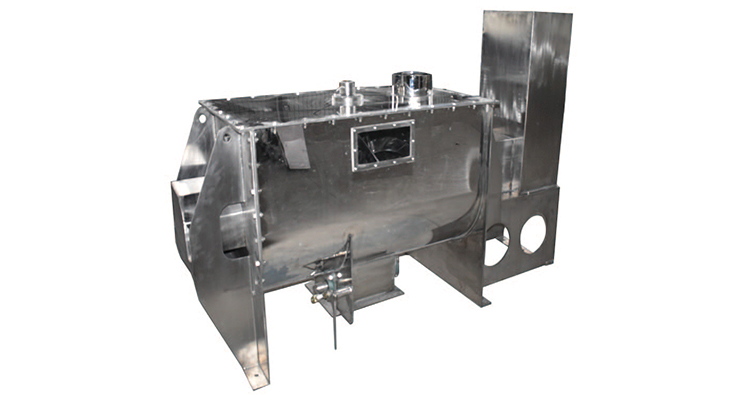

Horizontal Ribbon Mixer

1.Features

The mixing structure adopts spiral leaf belt, two layers inside and outside, which mixes evenly and fast;

For powder materials, the machine adopts large door controlled by pneumatic cylinder, with the advantages of fast discharge, less residue;

For high fineness materials or semi-fluid materials it use manual butterfly valve or pneumatic butterfly valve;

Manual butterfly valve is economical, and pneumatic butterfly valve provide a good seal against semi-fluid;

If heating needed, there are two ways of heating: electric heating and heat-conducting oil heating;

Carbon steel and Stainless steel are all available. If the material is too corrosive, you can choose a high grade stainless steel material or choose a corrosion resistant lining. The surface treatment can be rough polished, fine polished or mirror polished depending on the level of material used.

Technical parameters

| Working Volume | Operation Speed | Power | Size | Weight | Material Thickness | |

| Model | (L) | (rpm) | (kW) | (mm) | (kg) | (mm) |

| CTSBM-300 | 120-180 | 40 | 5.5 | 1300x950x1150 | 690 | 3 |

| CTSBM-500 | 200-300 | 40 | 7.5 | 1500x1100x1400 | 950 | 4 |

| CTSBM-1000 | 400-600 | 30 | 11 | 2000x1450x1550 | 1600 | 4 |

| CTSBM-1500 | 600-900 | 30 | 15 | 2200x1420x1790 | 1800 | 5 |

| CTSBM-2000 | 800-1200 | 30 | 15 | 2500x1500x1900 | 2000 | 5 |

| CTSBM-3000 | 1200-1800 | 30 | 18.5 | 2900x1900x2000 | 3100 | 5 |

| CTSBM-4000 | 1600-2400 | 25 | 22 | 3000x1900x2200 | 4100 | 6 |

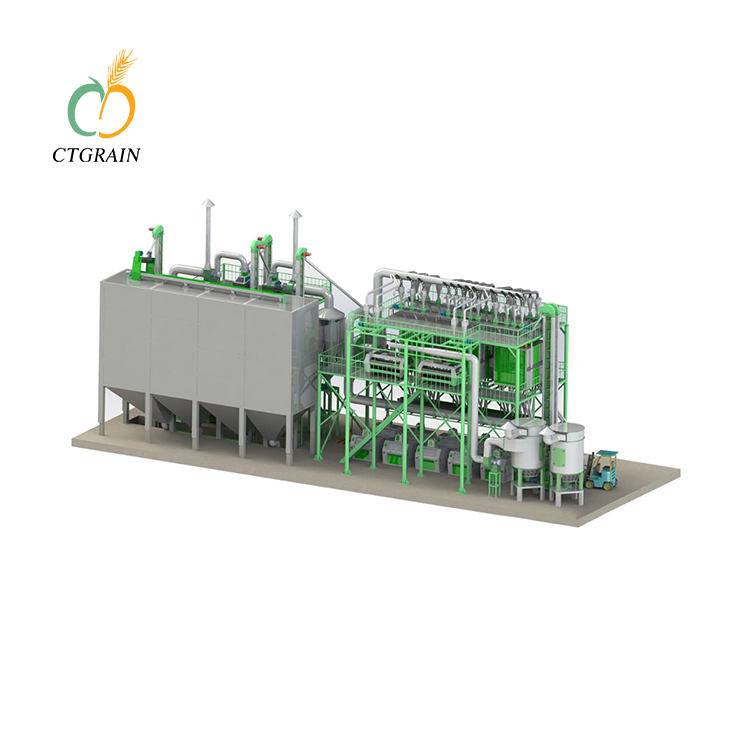

Application industry

It is widely used in the chemical, food, building material and pharmaceutical industries

The motor is directly connected to the mixing shaft by gearbox motor, with a simple structure, high operational reliability and easy maintenance.