High Efficiency Indented Cylinder Separator

Our FGJZ series indented cylinder is a grain cleaning and grading machine used for handling grains like wheat, barley, rice, corn, and so on. It can remove impurities that are shorter or longer than the grains, as well as classify the grains according to their lengths.

Our FGJZ series indented cylinder is a grain cleaning and grading machine used for handling grains like wheat, barley, rice, corn, and so on. It can remove impurities that are shorter or longer than the grains, as well as classify the grains according to their lengths.

This series indented cylinder grader, before delivery, will be subjected to several quality tests, making sure every product has the desirable quality and long service life. In addition, the delivery time is quite short.

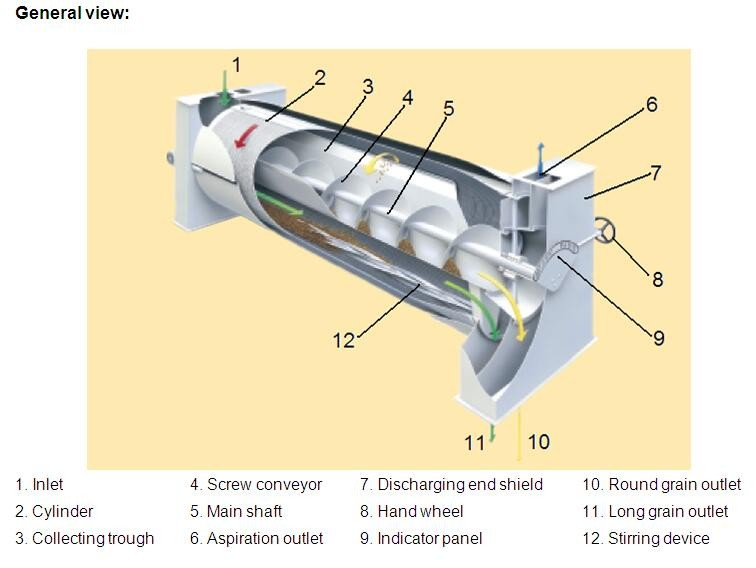

Working principle

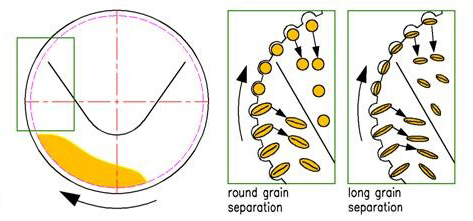

The material is fed at a uniform rate through the inlet directly into the rotating cylinder. As a result of the indented pockets in the jacket, the material

particles that can be accommodated in the pockets are elevated and thrown into the collection trough. The material in the trough is then discharged from the machine by a conveying screw; the material remaining inside the jacket or dropping back into it flows via the guiding device to the outlet of the Indented Separator. The separating efficiency of the machine can be controlled both by the selection of the pocket size and by adjustment of the separating trough (position of the trough rim). The high separating efficiency of the Indented Separator is further promoted by the adjustable retarding device installed in the cylindrical section of the Long-grain Separator. Aspiration connections at the important points of the Indented Separator ensure the dust-free operation of the machine.

Feature

1. The machine can effectively remove both the short and long impurities.

2. The modular design of the components and versatile feeding device make the cylinders change conveniently between series connection and parallel connection.

3. The cylinder is made of highly anti-wear material, so its service life is quite long.

4. The indented cylinder can be detached into two parts, and come with a rapid assembling device. Thus the operators can quickly and easily change the cylinders.

5. The indents are processed with a composite forming technique. The surface of the indented sieve is blunted, thus both the quality and durability can be improved.

Technical Parameters List

|

Type |

Capacity |

Power |

Air Volume |

Resistance |

Diameter× Length |

Cylinder Quantity |

Size (L×W×H) |

Weight |

|

t/h |

KW |

m3/h |

Pa |

mm |

pic |

mm |

kg |

|

|

FGJZ 60×1 |

1-1.5 |

1.1 |

200 |

60 |

600×2000 |

1 |

2760×780×1240 |

500 |

|

FGJZ 71×1 |

1.5-2 |

1.1 |

360 |

60 |

710×2500 |

1 |

3300×1100×1440 |

800 |

|

FGJZ 60×2 |

3-4 |

2.2 |

400 |

60 |

600×2000 |

2 |

2760×780×1900 |

1000 |

|

FGJZ 71×2 |

3.5-4 |

2.2 |

720 |

80 |

710×2500 |

2 |

3300×1100×2000 |

1700 |

|

FGJZ 60/71 |

4-5 |

2.6 |

400 |

60 |

710×2500 |

1 |

3280×1000×1900 |

1500 |

|

|

|

|

|

600×2500 |

1 |

|

|

|

|

FGJZ 60/71/71 |

7-8 |

4.1 |

800 |

60 |

710×2500 |

2 |

3400×1100×2570 |

2000 |

|

|

|

|

|

600×2500 |

1 |

|

|

|

|

FGJZ63×200A |

5 |

5.9 |

900 |

350 |

630×2000 |

3 |

3180×1140×2900 |

2250 |

|

FGJZ63×250A |

6.5 |

5.9 |

900 |

350 |

630×2500 |

3 |

3680×1140×2900 |

2430 |

|

FGJZ63×300A |

8 |

5.9 |

900 |

350 |

630×3000 |

3 |

4180×1140×2900 |

2600 |

|

FGJZ71×300A |

9 |

5.9 |

900 |

350 |

710×3000 |

3 |

4180×1140×3060 |

2800 |

|

FGJZ63×300H |

12 |

5.9 |

900 |

350 |

630×3000 |

3 |

4180×1140×2900 |

2350 |

|

FGJZ71×300H |

15 |

5.9 |

900 |

350 |

710×3000 |

3 |

4180×1140×2900 |

2550 |

Product Details

Cylinder

Customized according to different requirements

Pockets on Cylinder

High efficient to separate materials according to different size

About Us