Good quality Auto Loading Insect Destroyer Machine – FSJZG Series Latest Insect Destroyer – Chinatown

Good quality Auto Loading Insect Destroyer Machine – FSJZG Series Latest Insect Destroyer – Chinatown Detail:

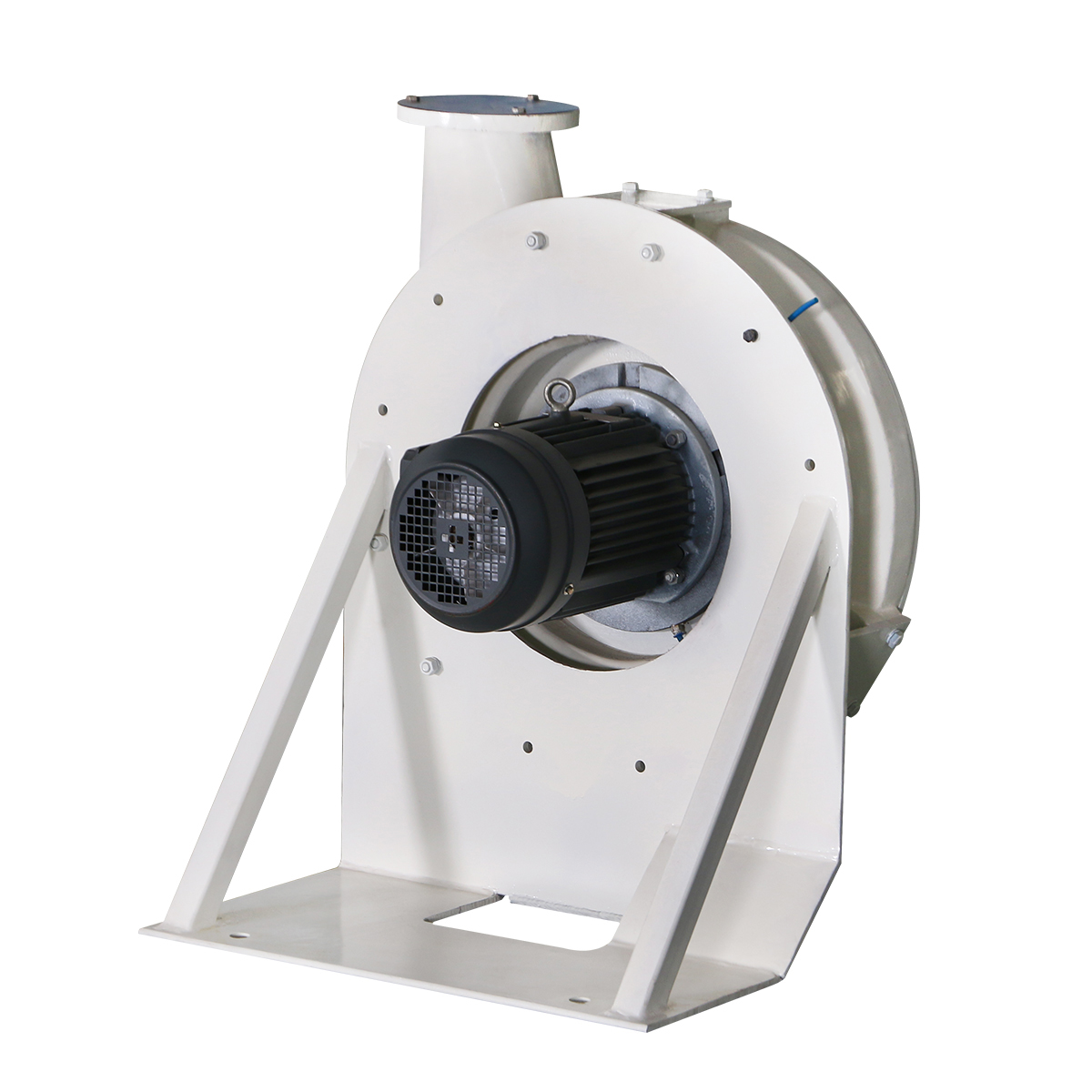

The optimal machine to kill the insect and its eggs

High-speed rotating, perfect impact result

For flour after the mill, before bin storage, or before packing

Insect destroyer for flour mill is applied before flour packing or it’s transferring to the bin, to effectively reduce the insects and their eggs. The high-speed rotating also leads to perfect impacting performance. Thus the flour storage endurance is greatly enhanced.

Specifications

Working principle

The material is fed into the machine from central inlet and is impacted fiercely by high-speed rotating rotor. Then the material leaves rotor in high linear speed rushing at pin and inner wall. During this process, the insects and the eggs are killed. Finally, the material is discharged from outlet.

Feature

1. The machine comes with a dynamically balanced rotor, ensuring smooth running.

2. Welded steel housing and anti-wear components are adopted for this equipment. The excellent durability leads to limited maintenance fees.

3. The impacting pins’ surfaces are thermally treated to achieve desirable wear resistance.

4. The round pins and square pins are optional for different passing properties and impact intensities.

5. Small area is needed for the installation of this flour-making equipment, and two installation types are optional. It can be mounted in the gravity conveying system or incorporated in the pneumatic conveying pipeline.

6. No floating dust will be generated and the repairing and operation are both very convenient.

7. A by-pass pipe and matching imported limit switch are installed. Thus when the machine stops, the mill system can continue to work.

8. The surface of the low carbon alloy steel pin, after being treated with nitriding and carbonization techniques, has become quite anti-wear.

Technical Parameters List

| ParameterType | Capacity | Power | Rotary Speed | Rotor diameter | Shape Size |

| t/h | KW | r/min | mm | L x W x H (mm) | |

| FSJZG-43 | 1.8 | 4 | 2900 | ф430 | 800x520x805 |

| 2.9 | 5.5 | 2900 | |||

| 4.7 | 7.5 | 2900 | |||

| FSJZG-51 | 4.5 | 15 | 2900 | ф510 | 800x690x850 |

| 6.2 | 18.5 | 2900 | |||

| 8.8 | 22 | 2900 | |||

| FSJZG-51D | 11-15 | 30 | 2900 | ф510 | 1081x800x850 |

| 15-18.5 | 37 | 2900 | |||

| 18.5-23 | 45 | 2900 |

Product Details

Rotary Pin

ABB Brand Motor

About Us

Product detail pictures:

Related Product Guide:

We insist on offering high-quality creation with superior business enterprise concept, honest revenue plus the greatest and fast service. it will bring you not only the high quality solution and huge profit, but essentially the most significant is usually to occupy the endless market for Good quality Auto Loading Insect Destroyer Machine – FSJZG Series Latest Insect Destroyer – Chinatown , The product will supply to all over the world, such as: Leicester, Slovenia, Kuala Lumpur, We are trying our best to make more customers happy and satisfied. we sincerely hope to establish a good long-term business relationship with your esteemed company thought this opportunity,based on equal, mutual beneficial and win win business from now till the future.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.