Food powder pneumatic transport machine vacuum feeder transfer system

Pneumatic conveying is a method of conveying materials through air flow, which has the advantages of high efficiency, environmental protection, and energy saving.

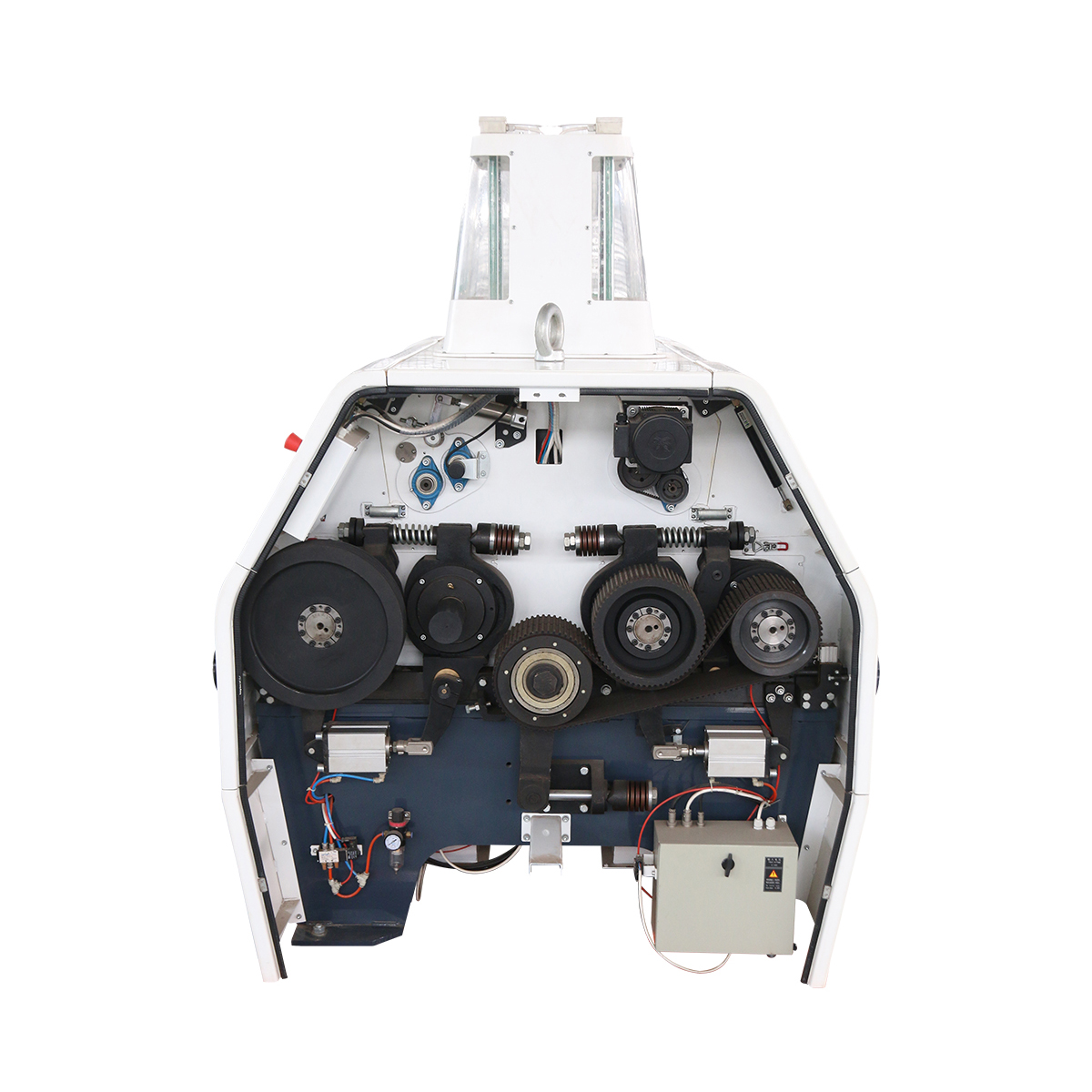

The vacuum feeder is one of the important equipment in the pneumatic conveying system. It uses vacuum to suck materials out of the storage hopper and transport them to the destination through the conveying pipe.

The distance and height of pneumatic conveying depend on the material, the performance of the conveying equipment and the design of the conveying pipe. Generally speaking, the distance of pneumatic conveying can reach tens of meters or even hundreds of meters, and the height of conveying can also reach tens of meters or even higher.

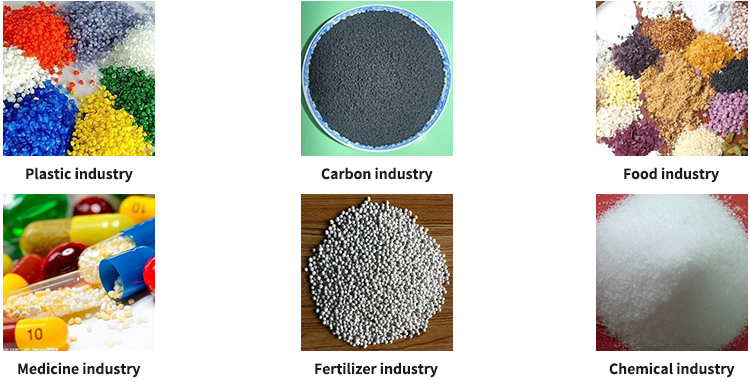

Pneumatic conveying is an efficient, environmentally friendly and energy-saving material conveying method, which is widely used in chemical, pharmaceutical, food and other industries.

Implementation function:

This solution can be used in continuous feeding situations, such as adapting to continuous mixer. Workers pour materials into the sieve, and the screened materials are then transported to the buffer hopper above the vector scale through negative transport. When the material in the vector scale is insufficient, the butterfly valve is opened, and the material quickly falls into the vector scale.

The vector scale controller collects weighing data and uses PID adjustment algorithm to control the screw speed to achieve stable and continuous feeding.

Application industry