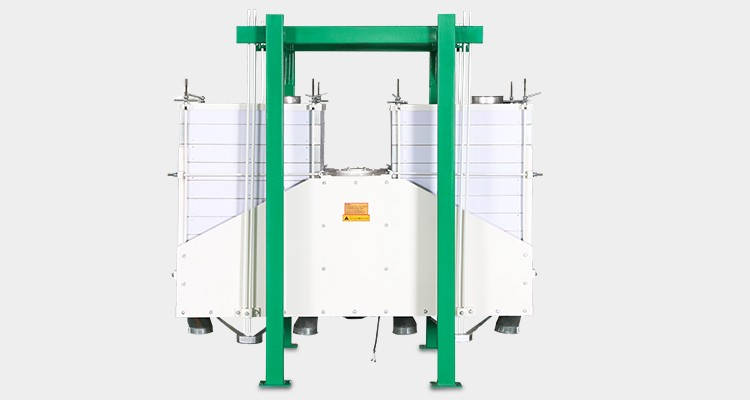

Flour Sifter Twin-Section Plansifter

The machine for sifting

The twin-section plansifter is a kind of practical flour milling equipment. It is mainly used for the last sieving between the sifting by plansifter and the flour packing in the flour mills, as well as the classification of pulverulent materials, coarse wheat flour, and intermediate, grinded materials. Currently, it has been widely adopted in modern flour mills and rice grinding mills. We can provide different sieving designs for different sifting performance and different intermediate materials.

Working principle

The Sifter is driven by a motor installed under the main frame to do plane rotary motion through the eccentric block. The material is fed into the inlet and flows down step by step according to respective design for different materials, and in the same time it is separated to several streams according to the particle size. The material can be separated into max. four types material. The flow sheet can be designed by different requirements.

Feature

1. The sieve frame size of the plansifter is available in 630×630mm, 700mm×700mm, 830mm×830mm, 100mm×100mm.

2. Modular design is introduced, so you can change the sieve frame quantity to get different sieving performance according to needs.

3. The adjustable counterweight is mounted with SKF (Sweden) bearings.

4. The sieve frames of the twin-section plansifter are made from imported wooden, and coated with plastic melamine lamination. They are demountable and interchangeable, and are equipped with stainless steel trays. Each whole section is clamped by a metal frame and pressure micrometric screws from the top. It is easy and quick to change the sifting scheme of the plansifter if necessary.

5. Our twin-section plansifter comes with two sections, so its production capacity is higher than that of the mono-section plansifter. It has small size, light weight, and only occupy a small place.

6. The sieves pack is suspended by its own frame which is installed on the floor or suspended by a separated frame fixed on the ceiling.

7. The SEFAR sieves are optional.

Technical Parameters List

|

Type |

Sifter Frame |

Sifting Area |

Main Shaft Speed |

Capacity |

Rotary |

Power |

Weight |

Shape Size |

|

(piece) |

(㎡) |

(r/min) |

(t/h) |

Diameter |

(kW) |

(kg) |

LxWxH(mm) |

|

|

FSFJ2x10x63 |

6-12 |

4.2 |

290 |

2-2.5 |

Ø45-55 |

1.1 |

550-580 |

1680x1270x1500 |

|

FSFJ2x10x70 |

8-12 |

6.2 |

265 |

3-3.5 |

Ø45-55 |

1.1 |

650-670 |

1840x1350x1760 |

|

FSFJ2x10x83 |

8-12 |

8.5 |

255 |

5-7 |

Ø45-55 |

1.5 |

730-815 |

2120x1440x2120 |

|

FSFJ2x10x100 |

10-12 |

13.5 |

255 |

8-10 |

Ø45-55 |

2.2 |

1200-1500 |

2530x1717x2270 |

Product Details

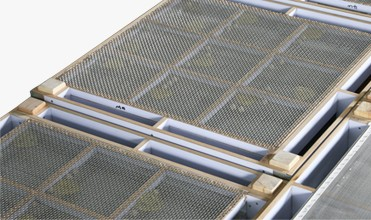

Open and closed compartment designs are both available. The sieve area of closed type is larger and the sealing is better.

Wooden sieve frame, plastic coated to avoid damp deformation, 6-12 sieve frame arrangement per different requirement.

Integrated vertical and horizontal compressing to ensure the sieve frame tight, no displacement, no inter- leakage.

Fiberglass rod suspension for stable running and short start-up and short-down time.

Customized sieve frame arrangement per different requirement

About Us