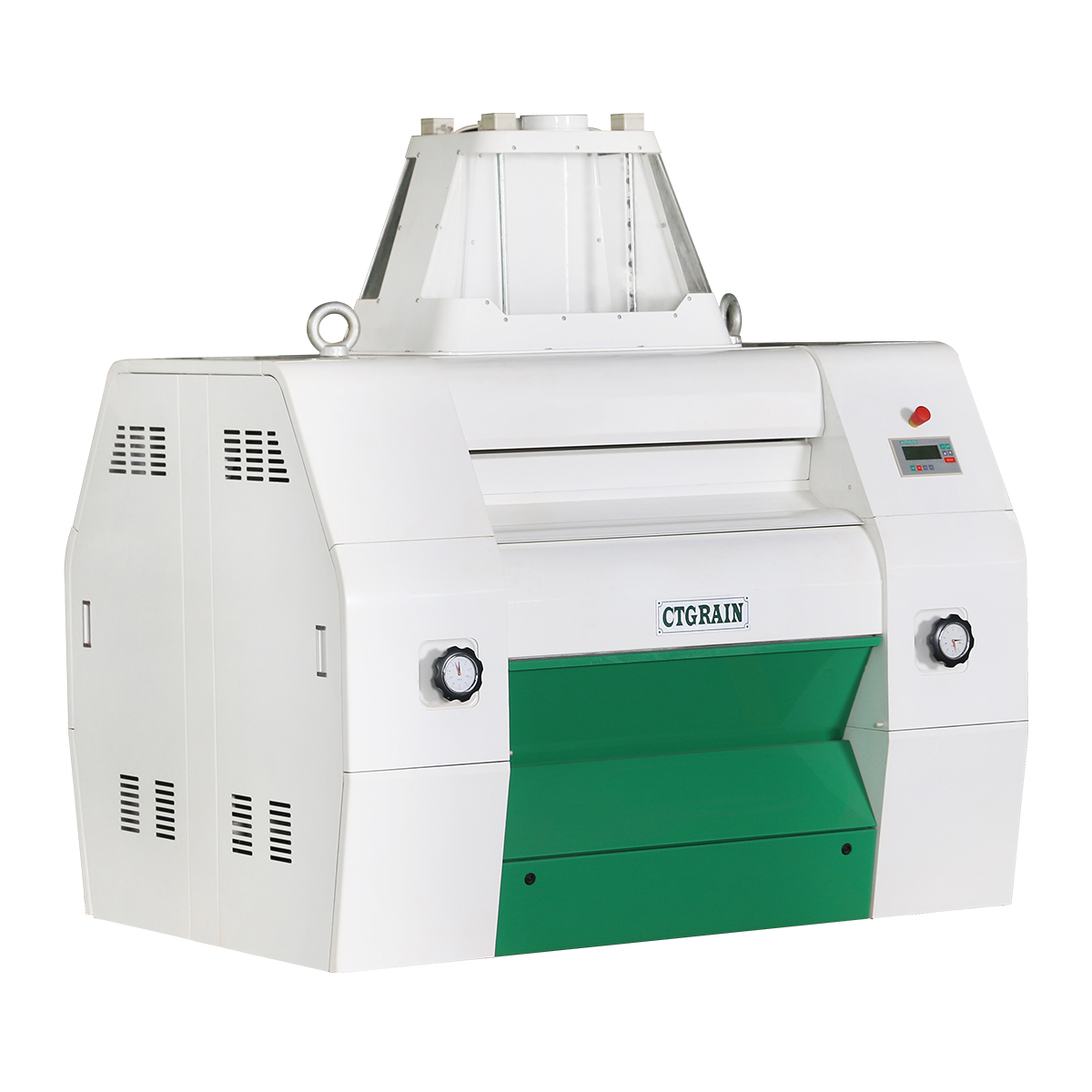

Factory source Flour And Semolina Mill Plant - Wheat Maize Electrical Roller Mill – Chinatown

Factory source Flour And Semolina Mill Plant - Wheat Maize Electrical Roller Mill – Chinatown Detail:

The machine for grain grinding

Widely used in Flour Mill, Corn Mill, Feed Mill and so on.

Working principle

After the machine start up, the rollers begin to rotate. The distance of two rollers is wider. During this period, there is no material fed into the machine from inlet. When engaging, the slower roller moves to faster roller normally, meanwhile, the feeding mechanism begins to feed material. At this time, the related parts of feeding mechanism and roller gap adjusting mechanism begin to move. If the distance of two rollers is equal to working roller gap, two rollers engaged and begin to grind normally. When disengaging, the slower roller leaves from faster roller, meanwhile, the feeding roller stops feeding material. The feeding mechanism makes the material flow into the grinding chamber stably and spreads the material on the roller working width uniformly. The working state of feeding mechanism is in accord with the working state of roller, feeding material or stopping material can be controlled by the feeding mechanism. The feeding mechanism can adjust the feeding rate automatically according to the volume of feeding material.

Features

1) Roller is made of centrifugal cast iron, dynamically balanced for a long working span.

2) Horizontal roller configuration and servo-feeder contribute to a perfect grinding performance.

3) Air aspiration design for the roller gap help to reduce the temperature of the grinding roller.

4) Automatic operation system makes it possible to display or modify the parameter very simply.

5) All the roller mills can be central controlled (e.g. engaged/disengaged) through PLC system and in control room center.

Technical Parameters List

| Type/Parameter | Length | Diameter | Feeding Motor | Weight | Shape Size |

| mm | mm | kw | kg | LxWxH(mm) | |

| MME80x25x2 | 800 | 250 | 0.37 | 2850 | 1610x1526x1955 |

| MME100x25x2 | 1000 | 250 | 0.37 | 3250 | 1810x1526x1955 |

| MME100x30x2 | 1000 | 300 | 0.37 | 3950 | 1810x1676x2005 |

| MME125x30x2 | 1250 | 300 | 0.37 | 4650 | 2060x1676x2005 |

Product Details

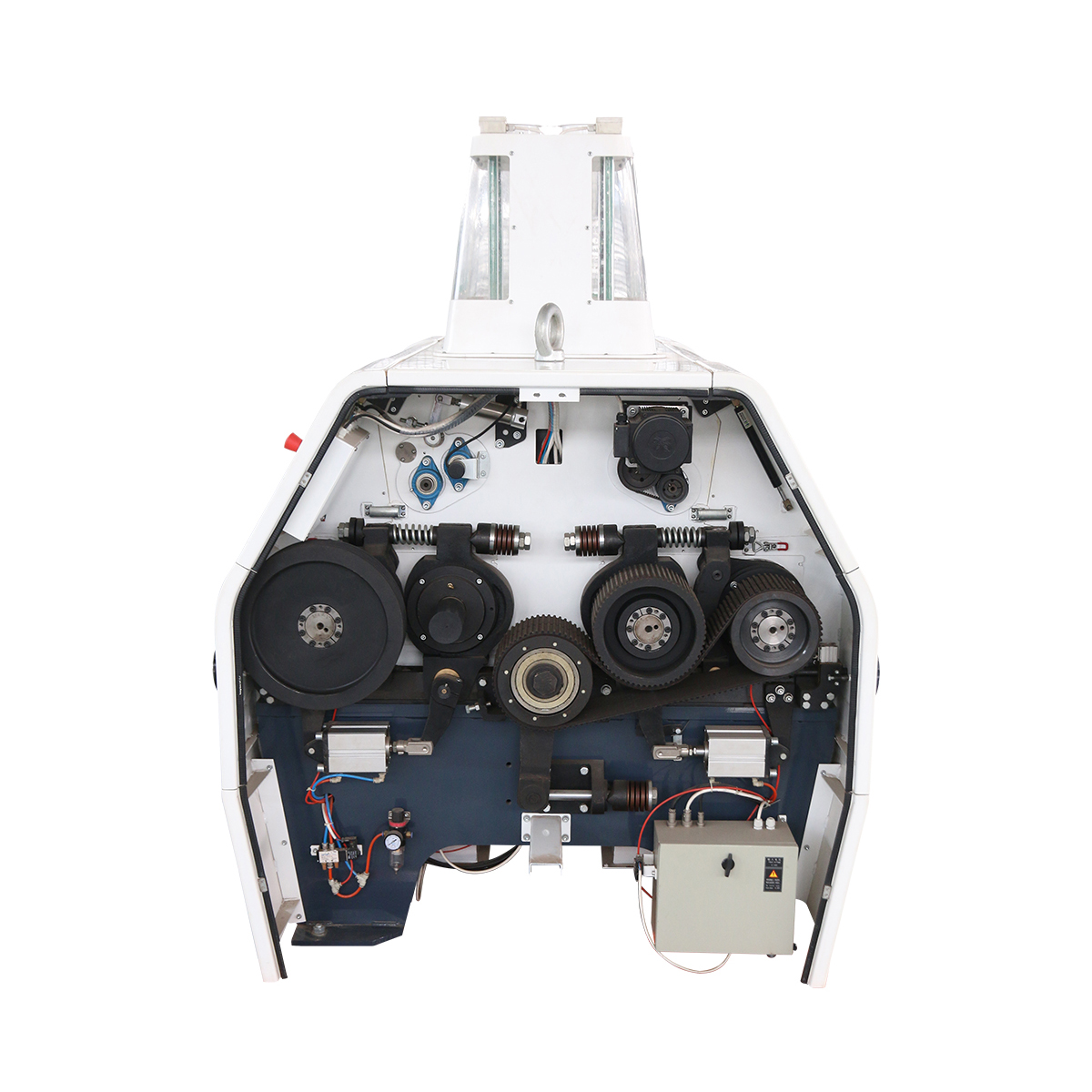

Level Sensor: The level sensor is controlled by infrared. Sensitive flow control, accurate feeding of feed roller avoid the frequent engage and disengage of roller and extend the service life of the roller.

Roller: Double metal centrifugal casting, high strength, and good wear resistance. Unbalance of the dynamic balance ≤ 2g. Total radial run-out < 0.008 mm. The shaft end is treated with 40Cr and the hardness is HB248-286. The hardness of roller surface: Smooth roller is Hs62-68, tooth roller is Hs72-78. Besides, the hardness distribution is uniform, and the hardness difference of the roller is ≤ Hs4. Long service life.

Roller Gap Adjusting: Visible roll gap adjusting, easy operation

Transmission Spring Tensioning Mechanism: Transmission spring tensioning mechanism can ensure the synchronous wedge belt transmit stably with low noise and long service life

About Us

Product detail pictures:

Related Product Guide:

We always work as a tangible team to ensure that we can provide you with the best quality and the best price for Factory source Flour And Semolina Mill Plant - Wheat Maize Electrical Roller Mill – Chinatown , The product will supply to all over the world, such as: Lisbon, Naples, Norway, we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, we have gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.